Timeway’equipment can be used to process body, turret, crankcase, cylinder head, auto parts, camera mould (cavity), shell, differential shell and other parts

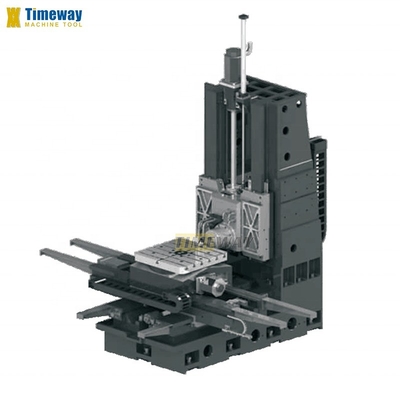

Max. Table Load of 600 kg High Precision Cnc Horizontal Machining Center for Metal

Product Details:

| Place of Origin: | China |

| Brand Name: | TIMEWAY |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $100,000.00/sets 1-2 sets |

| Packaging Details: | Woode case/Pallet |

| Supply Ability: | 150 Set/Sets per Month |

|

Detail Information |

|||

| Condition: | New | Spindle Taper: | BT40 |

|---|---|---|---|

| No. Of Spindles: | Single | Type: | Horizontal |

| Dimension(L*W*H): | 3500x2900x3280 | Weight (T): | 5.5 T |

| Table Size (mm): | Other | CNC Control System: | GSK |

| Number Of Axes: | 3 | Table Travel (X) (mm): | 800 |

| Table Travel (Y) (mm): | 600 | Table Travel (Z) (mm): | 500 |

| Positioning Accuracy (mm): | ±0.008 | Repeatability (X/Y/Z) (mm): | ±0.005 |

| Range Of Spindle Speed(r.p.m): | 1 - 8000 R.p.m | Spindle Motor Power(kW): | 11 |

| Max. Table Load(kg): | 600 Kg | Feed Speed(mm/min): | 1 - 8000 Mm/min |

| Min. Time Of Tool Change(s): | 3 | Tool Magazine Capacity: | 24 |

| Key Selling Points: | Automatic | Warranty: | 1 Year |

| Voltage: | 220V/380V/400v | Marketing Type: | Ordinary Product |

| Machinery Test Report: | Not Available | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | Machine Type: | Cnc Horizontal Machining Center |

| After-sales Service Provided: | Video Technical Support | Function: | Machining Metal |

| After Warranty Service: | Online | Model: | HMC500 |

| Control System: | GSK | Table Size: | 500x500mm |

| No. Of Axis: | 3 | X-axis Travel: | 800mm |

| Y-axis Travel: | 600mm | Applicable Industries: | Machinery Repair Shops, Manufacturing Plant, Other |

| Showroom Location: | Canada, France, Brazil, Peru, Indonesia, Mexico, Russia, Romania, Australia | Core Components: | Other |

| Rapid Feed Speed(m/min): | 11.1 | Port: | China Port |

Product Description

Products Description

Features

* Suitable for machining periodic parts * Suitable for machining parts with complex shapes * Suitable for machining high-efficiency and high-precision workpieces * For workpieces with suitable batch sizesSpecification | Unit | HMC500 | ||||

Machine structure | - | Cross-type | ||||

X axis travel | mm | 800 | ||||

Y axis travel | mm | 600 | ||||

Z axis travel | mm | 500 | ||||

B-axis servo motor torque (FANUC) | - | 8 | ||||

Table size | mm | 500×500 | ||||

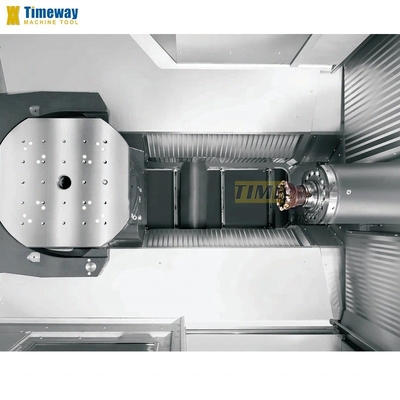

Table indexing | ° | 1°x360 | ||||

T-slot of worktable (No.-width/pitch) | - | 5-14-80 | ||||

Worktable rotation speed | rpm | 11.1 | ||||

loading capacity | kg | 600 | ||||

Locking force (35kg / cm2) | kg/m | 3000 | ||||

Distance spindle center to table | mm | 100-700 | ||||

Distance spindle nose to table center | mm | 140-640 | ||||

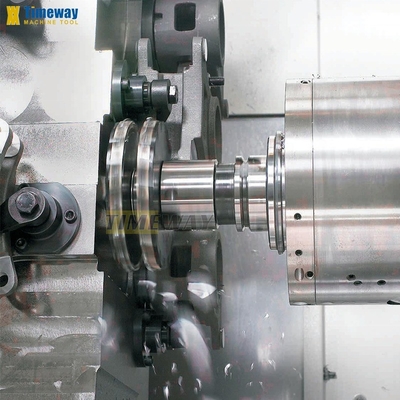

Spindle taper | - | BT40 | ||||

spindle speed | rpm | 8000 | ||||

Main motor power | kw | 11 | ||||

X/Y/Z-axis servo motor(FANUC) | - | Bis12/Bis12/Bis12 | ||||

X/Y/Z-axis cutting feed speed | mm/min | 1-8000 | ||||

X/Y/Z-axis rapid feed speed | m/min | 30/30/30 | ||||

X/Y/Z-axis rails type | - | Linear | ||||

X/Y/Z-axis positioning accuracy | mm | ±0.008 | ||||

X/Y/Z-axis repositioning accuracy | mm | ±0.005 | ||||

B-axis positioning accuracy | " | ±10" | ||||

ATC capacity(style) | tools | 24 (Disc) | ||||

Tool change time(tool to tool) | sec | 2.7 | ||||

Max. tool weight | kg | 8 | ||||

Max. tool diameter | mm | Φ78/Φ125 | ||||

Max. tool length | mm | 300 | ||||

Max. tool weight | kg | 8 | ||||

Power capacity | kva | 25 | ||||

Air pressure require | kg/cm2 | 8 | ||||

Machine weight | kg | 5500 | ||||

Overall dimension (L x W x H) | mm | 3500x2900x3280 | ||||

· Resin sand casting; · Adopt Taiwan precision linear guideway or hardened sliding guideawy; · X, Y, Z rails adopt telescopic cover for guideways · Standard with belt driven spindle; · Taiwan production pneumatic cylinder; · Taiwan ATC,disc type and chain type are available as option; · Imported bearings for leadsrews · Import coupling · Headstock balancing system have nitrogen balance system or hydraulic balance system as option; ·Work lamp ·Pilot lamp; | · ZF or BF reducer; · Circular Coolant Nozzle · Air conditioner (A/C) for electrical cabinet; · Spindle oil cooler · Auto. Tool length measurement system · Auto. Workpiece measurement systems |

Automatic tool changer is composed of tool magazine and tool changing arms. Automatic tool changer is installed separately from machine tool with thepurpose of preventing adverse influences of vibration during running of runningof automatic tool changer and other reasons on precision.

The spindle component is one of the execution components of the forming movement of the machining center, and the spindle component of the machining center is required to have high running accuracy, long-term accuracy retention and long-term accuracy stability.

The digital control system can control the machine tool to automatically select and replace the tools according to different processing procedures, and complete the multi-process processing on multiple surfaces of the workpiece in sequence.

Application field

Why Choose Us

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product