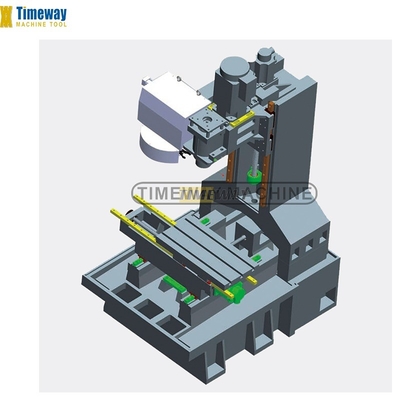

Vertical Machining Center with GSK CNC Control System from Machinery Repair Shops

Product Details:

| Place of Origin: | SHANGHAI |

| Brand Name: | TIMEWAY |

| Model Number: | VMC400G |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $20,000.00/sets 1-2 sets |

| Packaging Details: | Wooden cases(can be fumigated) |

| Supply Ability: | 150 Set/Sets per Month |

|

Detail Information |

|||

| Type: | VERTICAL | Range Of Spindle Speed(r.p.m): | 0 - 12 |

|---|---|---|---|

| Number Of Axes: | 3 | No. Of Spindles: | Single |

| Machining Capacity: | Medium Duty | Spindle Taper: | BT-30 |

| Table Travel (X) (mm): | 400 | Table Travel (Y) (mm): | 230 |

| Table Travel (Z) (mm): | 450 | Positioning Accuracy (mm): | 0.02 |

| Repeatability (X/Y/Z) (mm): | 0.01 | Voltage: | 380V |

| Dimension(L*W*H): | 2000x1900x2000 | CNC Control System: | GSK |

| Key Selling Points: | High-accuracy | Weight (KG): | 2300 |

| Spindle Motor Power(kW): | 2.2 | Warranty: | 1 YEAR |

| Max. Table Load(kg): | 150 Kg | Marketing Type: | Ordinary Product |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | Worktable Size (LxW): | 300x600 Mm |

| T-slot (No./width/pitch): | 3/14/100 Mm | Loading Capacity: | 150 Kg |

| Longitudinal Travel (X): | 400 Mm | Cross Travel (Y): | 230 Mm |

| Vertical Travel (Z): | 450 Mm | Distance From Spindle Nose To Table: | 100-580 Mm |

| Spindle Taper: | BT30 | Spindle Speed: | 6000 Rpm |

| Machine Weight: | 2300 Kg | Condition: | New |

| Applicable Industries: | Machinery Repair Shops, Construction Works | Showroom Location: | Indonesia, Russia, Spain, Chile, Nigeria |

| Core Components: | Motor, Engine | Table Travel (mm): | 400x230x450 |

| Year: | New | Port: | China Port |

Product Description

Products Description

SPECIFICATION | UNIT | VMC400G | VMC650G | VMC850G |

Worktable size (LxW) | mm | 300x600 | 1000x420 | 1000x500 |

T-slot (No./width/pitch) | mm | 3/14/100 | 5-18-80 | 5-18-100 |

Loading capacity | kg | 150 | 400 | 500 |

Longitudinal travel (X) | mm | 400 | 700 | 800 |

Cross travel (Y) | mm | 230 | 450 | 500 |

Vertical travel (Z) | mm | 450 | 450 | 500 |

Distance from spindle nose to table | mm | 100-580 | 130-630 | 110-610 |

Distance from spindle center to column | mm | 320 | 495 | 524 |

Spindle taper | - | BT30 (BT40) | BT-40 | BT-40 |

Spindle speed | rpm | 6000 | 8000 | 8000 |

X/Y/Z-axis rapid feed speed | m/min | 2012/12/10 | 48/48/48 | 48/48/48 |

X/Y/Z-axis servo motor (FANUC) | - | 0.75/0.75/1kw | β12/β12/β22 | β12/β12/β22 |

X/Y/Z-axis positioning accuracy | mm | 0.02 | ±0.003/300 | ±0.003/301 |

X/Y/Z-axis repositioning accuracy | mm | 0.01 | ±0.003/300 | ±0.003/301 |

Main motor power | kw | 2.2 (3.75) | 7.5/11 | 7.5/11 |

Air pressure source | kg/cm2 | 4/8 | 6/8 | 6/8 |

Power capacity | Kva | 10 | 18 | 20 |

Tool magazine capacity | T | 8/12 (Crousel) | 12 (Crousel) | 24 (Disc) |

Guideway type | - | Linear | Linear | Linear |

Machine weight | kg | 2300 | 3500 | 4200 |

Machine dimensions (LxWxH) | mm | 2000x1900x2000 | 2400x1900x2400 | 2800x2250x2600 |

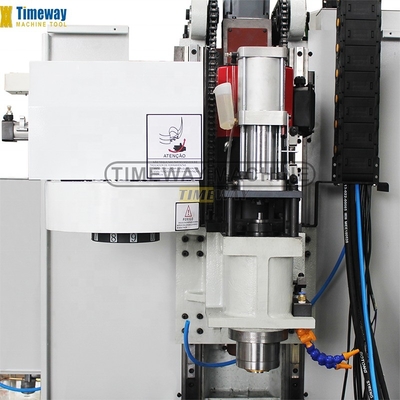

1. Resin sand casting; 2. X, Y rails adopts imported linear guideway; Z rails are quenching - plastic sliding guide rail pair; 3. X, Y, Z rails adopt stainless steel telescopic cover; 4. Standard with belt driven spindle, optional for direct driven spindle; 5. Taiwan production pneumatic cylinder; 6. Taiwan ATC, carousel type and disc type are available as option; 7. Imported bearings for leadscrews; 8. Import coupling; 9. Headstock balancing system have heavy casting or nitrogen balance system as option; 10. Full enclosure; 11. Rigid tapping; 12. Spindle center air blast; 13. Work lamp; 14. Pilot lamp; 15. USB and LAN interface; 16. Manual pulse generator (MPG); 17. Centralized automatic lubrication system. 18. Cooling system. 19. Heat exchanger for electrical cabinet ; 20. Leveling blocks & bolts; 21. Toolbox and tools; 22. CNC controller: KND,GSK, HNC (China); SIEMENS, FANUC, MITSUBISHI, FAGOR, etc. | 1. The 4th axis wiring; 2. NC rotary table; 3. Direct driven spindle (Speed: 10000rpm, 12000rpm, 15000rpm); 4. Circular Coolant Nozzle; 5. Coolant through spindle (CTS); 6. Spindle oil cooler; 7. Air conditioner (A/C) for electrical cabinet; 8. Auto. Tool length measurement system; 9. Auto. Workpiece measurement systems; 10. Screw type chip conveyor; 11. Chain type chip conveyor; 12. High pressure water flush system; 13. Safety door; 14. Oil skimmer. |

Hardened & Polished Table

24 Tools Disc-type ATC

Taiwan Spindel & Clamp Arm

Full Splash Guard

4-track Linear for Y-axis

Strengthened Spindle Box

RENISHAW Precise Test

High rigidity machine bed

Why Choose Us

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product