========================

>> Adopts positive T-type machine structure.

>> X/Z-axis adopt Taiwan HIWIN heavy-load Roller linear guide rails and HIWIN ball screw.

>> Hardened and fine ground worktable surface make sure high rigidity.

Multifunctional HMC630 CNC Horizontal Machining Center for metal manufacturing tasks

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | TIMEWAY TIMAC |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $75,000.00/sets 1-2 sets |

| Packaging Details: | Standard Package or As customer's requirement |

| Supply Ability: | 150 Set/Sets per Month |

|

Detail Information |

|||

| Condition: | New | Spindle Taper: | BT40 |

|---|---|---|---|

| No. Of Spindles: | Single | Type: | Horizontal |

| Dimension(L*W*H): | 4860x3600x3460mm | Weight (T): | 12 T |

| Table Size (mm): | 630x630 | CNC Control System: | FANUC |

| Number Of Axes: | 3, 4 | Table Travel (X) (mm): | 1100 |

| Table Travel (Y) (mm): | 800 | Table Travel (Z) (mm): | 1100 |

| Positioning Accuracy (mm): | ±0.008 | Repeatability (X/Y/Z) (mm): | ±0.005 |

| Range Of Spindle Speed(r.p.m): | 1 - 6000 R.p.m | Spindle Motor Power(kW): | 15/18.5 |

| Max. Table Load(kg): | 1500 Kg | Feed Speed(mm/min): | 1 - 8000 Mm/min |

| Min. Time Of Tool Change(s): | 5 | Tool Magazine Capacity: | 24 |

| Key Selling Points: | Flexible Manufacturing | Warranty: | 1 Year |

| Voltage: | 380V/50Hz Or Order | Marketing Type: | Hot Product 2022 |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | Table Size: | 630x630 |

| Number Of Axis: | 3 | X-axis Travel: | 1100 |

| Y-axis Travel: | 800 | Product Name: | Horizontal Milling Machine |

| Machine Type: | Horizontal Machining Center | Product Type: | Machining Center Cnc Mill Machine |

| Keywords: | Horizontal Cnc Milling Machine | Name: | Milling Cnc Machine |

| Key Selling Points: | Competitive Price | Applicable Industries: | Machinery Repair Shops, Manufacturing Plant, Energy & Mining |

| Showroom Location: | Canada, United Kingdom, United States, Italy, France | Rapid Feed Speed(m/min): | 24/24/24 |

| Core Components: | FANUC | Port: | China Port |

Product Description

Horizontal Machining Center CNC Milling Machine

Products Description

Applications of the vertical machining center:

The HMC series horizontal machining center is a CNC horizontal machining center controlled by CNC (computer numerical control

device) and performing cutting processing. It can perform drilling, tapping and milling; it can solve the processing of complex,

precise, small batch, and multi-variety parts.

Standard equipped with B axis (NC rotary table) dividing processing requirement.

The structure of HMC horizontal machining center can divide into three kinds: Positive T-type; Inverted T-type; Cross-type.

Realize various processing requirements of the different size and different shape workpieces.

device) and performing cutting processing. It can perform drilling, tapping and milling; it can solve the processing of complex,

precise, small batch, and multi-variety parts.

Standard equipped with B axis (NC rotary table) dividing processing requirement.

The structure of HMC horizontal machining center can divide into three kinds: Positive T-type; Inverted T-type; Cross-type.

Realize various processing requirements of the different size and different shape workpieces.

Specification | Unit | HMC630 |

X-axis travel | mm | 1100 |

Y-axis travel | mm | 800 |

Z-axis travel | mm | 1100 |

Table size | mm | 630×630 |

Loading capacity | kg | 1500 |

Locking force (35kg / cm2) | kg/m | 5000 |

Distance spindle center to table | mm | 50-850 |

√ FANUC 0i MF CNC system√ X/Z: Linear guide rails, Y: Sliding guide rail

√ Taiwan BT50 spindle, 6000rpm

√ Taiwan NC rotary table (B-axis)

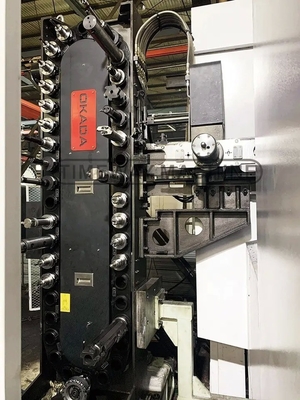

√ Taiwan disc-type ATC with 24tools

√ Full enclosure

√Manual pulse generator (MPG)

√ USB & LAN interface

√ Work lamp

√ Pilot lamp

√ Cooling system

√ Centralized automatic lubrication system

√ Spindle air blast

√ Air gun

√ Milling arbor & chuck

√ Heat exchanger for electric cabinet

√ Tools & tool-box

√ Leveling wedge & bolts

√ Operation manual (English)

√ Taiwan BT50 spindle, 6000rpm

√ Taiwan NC rotary table (B-axis)

√ Taiwan disc-type ATC with 24tools

√ Full enclosure

√Manual pulse generator (MPG)

√ USB & LAN interface

√ Work lamp

√ Pilot lamp

√ Cooling system

√ Centralized automatic lubrication system

√ Spindle air blast

√ Air gun

√ Milling arbor & chuck

√ Heat exchanger for electric cabinet

√ Tools & tool-box

√ Leveling wedge & bolts

√ Operation manual (English)

_ MITSUBISHI/SIEMENS/FAGOR/GSK/HNC/KND

_ Direct driven spindle (10000, 12000, 15000rpm)

_ Circular coolant nozzle

_ Coolant through spindle (CTS)

_ Spindle oil cooler

_ Air conditioner

_ Chain-type chip conveyor

_ Water gun

_ Safety door

_ Tool measurement system

_ Workpiece measurement system

_ Direct driven spindle (10000, 12000, 15000rpm)

_ Circular coolant nozzle

_ Coolant through spindle (CTS)

_ Spindle oil cooler

_ Air conditioner

_ Chain-type chip conveyor

_ Water gun

_ Safety door

_ Tool measurement system

_ Workpiece measurement system

Machine details:

========================

>> B-axis: Taiwan 1° NC rotary table comes standard, customer can choose 0.001° NC rotary table.

>> Large working space can meet the processing requirement of different size pieces.>> Stainless steel telescopic cover can

protect effectively the machine guideways and ball screw from damage.

>> B-axis: Taiwan 1° NC rotary table comes standard, customer can choose 0.001° NC rotary table.

>> Large working space can meet the processing requirement of different size pieces.>> Stainless steel telescopic cover can

protect effectively the machine guideways and ball screw from damage.

========================

>> Choose Taiwan BT50 chain-type tool magazine (40tools ATC), with high concentricity, low noise, fast tool change, high

precision, long service life.

>> Choose Taiwan BT50 chain-type tool magazine (40tools ATC), with high concentricity, low noise, fast tool change, high

precision, long service life.

Positive Comments From Customers

Company Introduction

Factory Display:

Text Introduction:

Company Profile:

Timeway Machine Tool Co., Ltd. is a professional machine tool manufacturing enterprises, the main products include lathe, milling machine, grinding machine, etc., and according to customer needs we also can design and manufacture various special purpose machines, to provide relative technology upgrading and transformation services in machine tool field.

Our factory was established in 2014. It has professional technicians, a research and development team, manufactures and sells CNC equipment and provides professional customized services.Our products are widely used in mold processing, 3C products, agricultural machinery, petroleum machinery, auto parts processing, aerospace industry, etc., selling more than 60 countries and regions in domestic and abroad.

FAQ

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price; 2 . Professional R&D team and 25 years export experience; 3 . Exported more than 60 countries; 4 . CE, ISO Certificates; 5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager); 6 . 12 months quality warranty; 7 . Oversea engineers available for problem resolving; Q: Do you have QC or any safety standards for your machinery? A: yes, we have established a highly strict quality control department to guanrantee good quality. Q: What's the MOQ? A: 1 set (Only some low cost machines will be more than 1 set ) Q: What about the payment terms? A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment; (2) Irrevocable LC at sight; (3) Western Union, MoneyGram, etc. Q: How about the warranty? A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product