1100/800/1100mm X/Y/Z Axis Travel CNC Horizontal Machining Center HMC630 3-Axis Machine

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | timeway |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $68,000.00/sets 1-2 sets |

|

Detail Information |

|||

| Condition: | New | Spindle Taper: | BT50 |

|---|---|---|---|

| No. Of Spindles: | Single | Type: | Horizontal |

| Dimension(L*W*H): | 4860*3600*3460 | Weight (T): | 12 KG |

| Table Size (mm): | 630*630 | CNC Control System: | GSK |

| Table Travel (X) (mm): | 1100 | Table Travel (Y) (mm): | 800 |

| Table Travel (Z) (mm): | 1100 | Positioning Accuracy (mm): | 0.008 |

| Repeatability (X/Y/Z) (mm): | 0.005 | Range Of Spindle Speed(r.p.m): | 0 - 6000 R.p.m |

| Max. Table Load(kg): | 1500 Kg | Feed Speed(mm/min): | 1 - 8000 Mm/min |

| Min. Time Of Tool Change(s): | 3 | Tool Magazine Capacity: | 24 |

| Key Selling Points: | Automatic | Warranty: | 1 Year |

| Marketing Type: | New Product 2024 | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 1 Year |

| Machining Capacity: | Heavy Duty | Spindle Bore(mm): | 0 |

| Cutting Torque: | 12 N.m | Rapid Feed Speed(mm/min): | 0 - 3000 Mm/min |

| Product Name: | Horizontal CNC Milling Machine | Machine Type: | Horizontal Machine Centers |

| Model: | HMC630 | Color: | Customer's Requirement |

| Control System: | SIEMENS GSK FANUC (optional) | Spindle Speed: | 6000RPM |

| After-sales Service Provided: | 1 Year | X/Y/Z Axis Travel: | 1100/800/1100mm |

| Worktable Size: | 630*630mm | Motor: | 11kw |

Product Description

Products Description

CNC Horizontal Machining Center (HMC) Positive T-Type

HMC630

Three-axis heavy roller guide with integrated high speed Mechanical spindle, Can deal with from high speed, high precision to heavy cutting processing, from aluminum parts, steel parts to casting and other materials processing.Application areas: automotive, aerospace, petroleum, electric power, locomotive, plastic machinery, construction machinery and other industries of precision machining.

1. The internal reinforced frame design of the base ensures that the base does not change shape, strong vibration absorption ability, and greatly improves the cutting rigidity.

2. Stable triangular structure + double reinforcement plate, improve the overall rigidity of the column. 3. The standard three-axis screw hollow cooling can reduce the temperature rise of the screw by

70%.

70%.

4. Z-axis guide rail with long span provides stable support.

Specification

Specification | Unit | HMC630 |

Machine structure | - | Positive T-type |

X-axis travel | mm | 1100 |

Y-axis travel | mm | 800 |

Z-axis travel | mm | 1100 |

B-axis servo motor torque(FANUC) | - | Bis22 |

Table size | mm | 630x630 |

Table indexing | ° | 1°x360 |

T-slots (No./width/pitch) | - | 5-18-100 |

Table rotation speed | rpm | 16.6 |

Loading capacity | kg | 1500 |

Locking force(35kg/cm2) | kg/m | 5000 |

Distance spindle center to table | mm | 50-850 |

Distance spindle nose to table center | mm | 125-1225 |

Spindle taper | - | BT50 |

Spindle speed | rpm | 6000 |

X/Y/Z-axis servo motor (FANUC) | - | Bis30/Bis30/Bis30 |

X/Y/Z-axis cutting feed speed | mm/min | 1-8000 |

X/Y/Z-axis rapid feed speed | m/min | 24/24/24 |

X/Y/Z-axis rails type | - | X/Z:Linear; Y: sliding |

X/Y/Z-axis positioning accuracy | mm | 0.008 |

X/Y/Z-axis repositioning accuracy | mm | 0.005 |

B-axis positioning accuracy | '' | 10'' |

ATC capacity (style) | tools | 24(Disc) |

Tool change time (tool to tool) | sec | 5 |

Max. tool weight | kg | 18 |

Max. tool diameter | mm | 112/200 |

Max. tool length | mm | 300 |

Power supply | Kva | 40 |

Air pressure require | kg/cm2 | 8 |

Machine weight | kg | 12000 |

Machine dimensions (LxWxH) | mm | 4860×3600×3460 |

Accessories

· SIEMENS 808D control · Manual pulse generator (MPG) · USB &LAN interface · Work lamp · Pilot lamp · Cooling system · Auto. lubrication system · Leveling wedge and bolts · NC rotary table · Heat exchanger · Tool & tool box · Operator manual(English) | · ZF or BF reducer · Circular coolant nozzle · Coolant through spindle (CTS) · Spindle oil cooler · Air conditioner for electrical cabinet · Auto. tool length measurement system · Auto. workpiece measurement system · Chip conveyor (opt.: sprial type/chain type) |

Detailed Images

High rigidity bed design

X, Z-axis integrated bed, Y axis column integrated molding design, the overall rigidity is excellent, can improve the accuracy and stability of machine tools.

Strong BT-50 spindle transmission device

The gear spindle head is cast in one piece, which is more rigid than the general combined spindle structure, improves the stability of the machine tool, and has stronger cutting ability and higher accuracy.

High precision rotary table

The disk of B-axis rotating worktable is driven by SIEMENS AC servo motor. The hydraulic clamping system is adopted to ensure high precision and high rigidity.

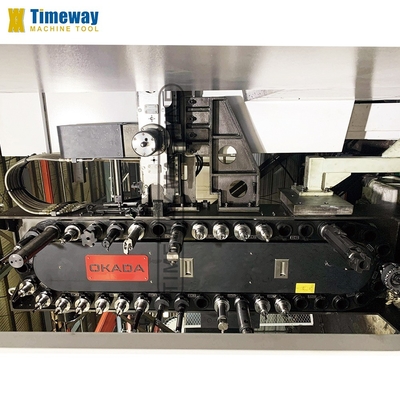

Chain Type ATC

Using the shortest path fixed address address method, so the collision problem of large tools can only be considered in the first installation.

Application Field

Our Services

1. Free replacing parts available in the warranty period. Cost price replacing parts available beyond the warranty period. 2. Quick action and reply for the technical questions at any time in the whole life of the machine. 3. Overseas after service center available in some region. 4. Engineer overseas service available on the requirement of customer(relative cost born by customer).

Company Introduction

Factory Display:

Factory Profile:

Our factory was established in 2014. It has professional technicians, a research and development team, manufactures and sells CNC equipment and provides professional customized services.Our products are widely used in mold processing, 3C products, agricultural machinery, petroleum machinery, auto parts processing, aerospace industry, etc., selling more than 60 countries and regions in domestic and abroad.

Text Introduction:

Company Profile:

Timeway Machine Tool Co., Ltd. is a professional machine tool manufacturing enterprises, the main products include lathe, milling machine, grinding machine, etc., and according to customer needs we also can design and manufacture various special purpose machines, to provide relative technology upgrading and transformation services in machine tool field.

Customer Visited:

So far, we have received many customers from abroad, and they are all very satisfied with our company and products.

Exhibitions:

Since the establishment of the Ministry of Foreign Trade, we have participated in various domestic and international exhibitions such as the Autumn Canton Fair, Beijing Exhibition, Shanghai Exhibition, Moscow, Ethiopia, and Russia, and have maintained long-term friendly cooperative relations with exhibition customers.

FAQ

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price; 2 . Professional R&D team and 25 years export experience; 3 . Exported more than 60 countries; 4 . CE, ISO Certificates; 5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager); 6 . 12 months quality warranty; 7 . Oversea engineers available for problem resolving; Q: Do you have QC or any safety standards for your machinery? A: yes, we have established a highly strict quality control department to guanrantee good quality. Q: What's the MOQ? A: 1 set (Only some low cost machines will be more than 1 set ) Q: What about the payment terms? A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment; (2) Irrevocable LC at sight; (3) Western Union, MoneyGram, etc. Q: How about the warranty? A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product