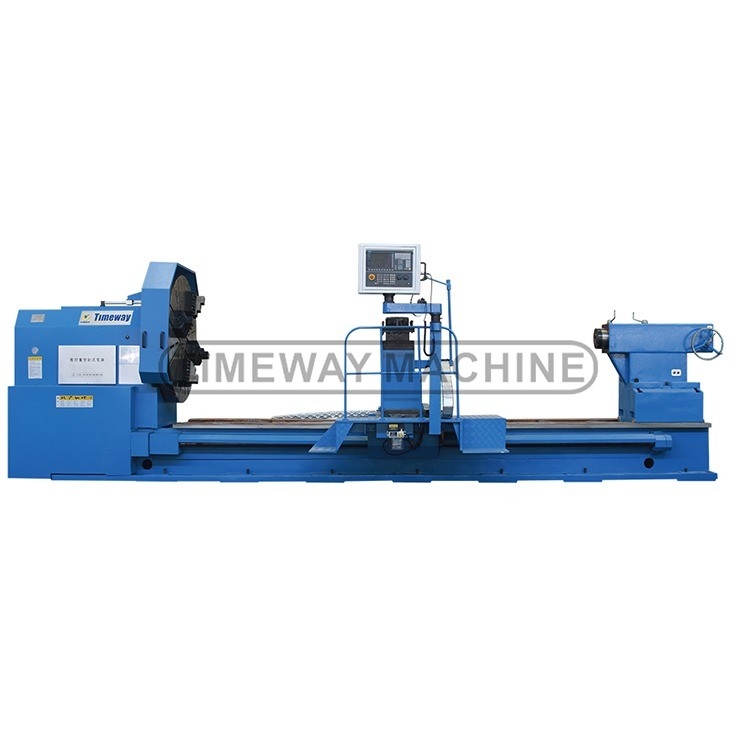

Made In Heavy Duty Flat Horizontal CNC Machine with 320 r.p.m Max. Spindle Speed

Product Details:

| Place of Origin: | China |

| Brand Name: | TIMAC |

| Model Number: | AK-1250/AK-1600/AK-1800/AK-2000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $110,000.00/sets 1-2 sets |

| Packaging Details: | Wooden cases(can be fumigated) |

| Supply Ability: | 150 Set/Sets per Month |

|

Detail Information |

|||

| Type: | Horizontal | Max. Length Of Workpiece (mm): | 12000 |

|---|---|---|---|

| Structure: | Flat Bed Lathe | Machining Capacity: | Heavy Duty |

| Max. Weight Of Workpiece(kg): | 16000 | Width Of Bed (mm): | 1100 Mm |

| Spindle Motor Power(kW): | 30 | No. Of Spindles: | Single |

| Number Of Axes: | 2 | Travel (X Axis)(mm): | 850 Mm |

| Travel (Z Axis)(mm): | 500 Mm | Positioning Accuracy (mm): | 0.03 Mm |

| Repeatability (X/Y/Z) (mm): | 0.012 | Dimension(L*W*H): | 15700x3200x2850 |

| Voltage: | 220V/380V | CNC Control System: | FANUC |

| Tool Post Stations: | 4 | Weight (KG): | 34800 |

| Warranty: | 1 Year | Key Selling Points: | Multifunctional |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | Swing Over Bed: | 1250 |

| Swing Over Carriage: | 900 | Max. Length Of Workpiece: | 3000/5000/6000/8000/10000/12000 |

| Max. Turning Length: | 2800/4800/5800/7800/9800/11800 | Span Of Guideway: | 2800/4800/5800/7800/9800/11800 1100 |

| Chuck Diameter: | 1250 | Max. Weight Of Workpiece: | 16 |

| Spindle Nose: | A2-15 | Spindle Bore: | 100 |

| Taper Hole Of Spindle: | Metric 140 | Condition: | New |

| Spindle Bore(mm): | 100 | Toolpost Brand: | Pragati |

| Applicable Industries: | Machinery Repair Shops, Manufacturing Plant, Home Use, Retail, Construction Works , Energy & Mining | Showroom Location: | Egypt, Canada, Turkey, United Kingdom, Italy, France, Germany, Viet Nam, Philippines, Brazil, Peru, Saudi Arabia, Indonesia, Pakistan, India, Mexico, Russia, Spain, Thailand, Morocco, Kenya, Argentina, South Korea, Chile, UAE, Colombia, Algeria, Sri Lanka, |

| Core Components: | Other | Max. Turned Length (mm): | 12000 |

| Marketing Type: | Other | Max. Spindle Speed (r.p.m): | 320 R.p.m |

| Port: | China Port | ||

Product Description

Products Description

Application:

This pneumatic forging hammer is widely used for general forging works, such as drawing-out, upsetting, punching, chiseling, forge, welding, bending and twisting. It is also used for forging in bolster dies.

Features:

---This series machine bed as a whole box-shaped structure, the use of high standard cast iron (HT300) a molding casting, after the second aging treatment, stable performance; rail span (1100mm), good rigidity, anti-vibration ability.

---The spindle bore is 100mm, the box structure is strong, suitable for heavy processing.

---Spindle speed can be 33 speeds by manual shift; Automatic shift speed control by the M-code, the automatically variable speed selection by S- code control, achieve stepless speed and constant linear cutting.

---Equipped with 4-station vertical electric tool-post, but also according to their own needs with 6-station or 8-station variety of electric tool-post.

---Spindle motor adopts the 30kw three-phase AC asynchronous motor, the output of large, variable range. Equipped with heavy duty four-jaw chuck.

---Tailstock structure is strong, can withstand heavy cutting, standard electric tailstock, to achieve automatic rapid movement, improve efficiency.

---CNC system uses the world's most well-known SIEMENS 828D control system (also available according to user requirements matching other systems), can simultaneously control the 2-axis (X, Z), and has a straight line, arc and thread interpolation and other fixed cycle and other

functions, the minimum resolution of 0.001mm.

---Equipped with emergency stop safety button, when the machine suddenly encountered a sudden power failure or self-failure, due to the special design of the control circuit, the machine can be self-protection, to ensure that the machine and personnel safety, The control program has been "solidified" in the chip, will not be lost, because of it is stored in the program menu.

---This series of machine is based on the international market, the latest development trend of CNC lathes developed with semi-closed-loop control of the universal CNC lathes. The machine is widely used, flexible operation, suitable for processing all kinds of complex shape of the

shaft, disk parts, such as turning inner and outer cylindrical surface, conical surface, circular surface, end face, slot, chamfer, Especially for multi-species, small batch of turns processing, process adaptability, processing efficiency, low scrap rate, good consistency of the finished

product, can reduce the technical requirements of the workers skilled. Easy programming, easy operation, is the ideal large-scale mechanical processing equipment.

This pneumatic forging hammer is widely used for general forging works, such as drawing-out, upsetting, punching, chiseling, forge, welding, bending and twisting. It is also used for forging in bolster dies.

Features:

---This series machine bed as a whole box-shaped structure, the use of high standard cast iron (HT300) a molding casting, after the second aging treatment, stable performance; rail span (1100mm), good rigidity, anti-vibration ability.

---The spindle bore is 100mm, the box structure is strong, suitable for heavy processing.

---Spindle speed can be 33 speeds by manual shift; Automatic shift speed control by the M-code, the automatically variable speed selection by S- code control, achieve stepless speed and constant linear cutting.

---Equipped with 4-station vertical electric tool-post, but also according to their own needs with 6-station or 8-station variety of electric tool-post.

---Spindle motor adopts the 30kw three-phase AC asynchronous motor, the output of large, variable range. Equipped with heavy duty four-jaw chuck.

---Tailstock structure is strong, can withstand heavy cutting, standard electric tailstock, to achieve automatic rapid movement, improve efficiency.

---CNC system uses the world's most well-known SIEMENS 828D control system (also available according to user requirements matching other systems), can simultaneously control the 2-axis (X, Z), and has a straight line, arc and thread interpolation and other fixed cycle and other

functions, the minimum resolution of 0.001mm.

---Equipped with emergency stop safety button, when the machine suddenly encountered a sudden power failure or self-failure, due to the special design of the control circuit, the machine can be self-protection, to ensure that the machine and personnel safety, The control program has been "solidified" in the chip, will not be lost, because of it is stored in the program menu.

---This series of machine is based on the international market, the latest development trend of CNC lathes developed with semi-closed-loop control of the universal CNC lathes. The machine is widely used, flexible operation, suitable for processing all kinds of complex shape of the

shaft, disk parts, such as turning inner and outer cylindrical surface, conical surface, circular surface, end face, slot, chamfer, Especially for multi-species, small batch of turns processing, process adaptability, processing efficiency, low scrap rate, good consistency of the finished

product, can reduce the technical requirements of the workers skilled. Easy programming, easy operation, is the ideal large-scale mechanical processing equipment.

Specifications | Unit | AK-1250 | AK-1600 | AK-1800 | AK-2000 | |||

Swing over bed | mm | 1250 | 1600 | 1840 | 2000 | |||

Swing over carriage | mm | 900 | 1250 | 1450 | 1600 | |||

Max. length of workpiece | mm | 3000/5000/6000/8000/10000/12000 | 3000/5000/6000/8000/10000/12000 | 1000-16000 | 3000/5000/6000/8000/10000/12000 | |||

Max. turning length | mm | 2800/4800/5800/7800/9800/11800 | 2800/4800/5800/7800/9800/11800 | 2800/4800/5800/7800/9800/11800 | ||||

Span of guideway | mm | 1100 | 1100 | 1100 | 1100 | |||

Chuck diameter | mm | 1250 | 1400 | 1600 | 1600 | |||

Max. weight of workpiece | t | 16 | 16 | 16 | 16 | |||

Spindle nose | mm | A2-15 | A2-15 | A2-15 | ||||

Spindle bore | mm | 100 | 100 | 130 | 100 | |||

Taper hole of spindle | - | Metric 140 | Metric 140 | Metric 140 | Metric 140 | |||

Spindle speed range (stepless) | rpm | 3-320 | 3-320 | 3-200 | 3-320 | |||

Spindle speed range (manual steps) | rpm | CCW: 3.15-315(21); CW: 3.5-291(12) | CCW: 3.15-315(21); CW: 3.5-291(12) | CCW: 3.15-315(21); CW: 3.5-291(12) | ||||

Max. cutting power | N | 39200 | 39200 | 39200 | ||||

Rapid speeds of X-/Z-axis | mm/min | 4000/6000 | 4000/6000 | 4000/4000 | 4000/6000 | |||

Max. travel of X-axis | mm | 850 | 850 | 850 | ||||

Turret working position | - | V4 | V4 | V4 | V4 | |||

Size of turret | mm | 380x380 | 380x380 | 380x380 | ||||

Max. feed force | N | 10875 | 10875 | 10875 | ||||

Section of tool shank | mm | 50x50 | 50x50 | 55x55 | 50x50 | |||

Dia. of tailstock quill | mm | 260 | 260 | 260 | 260 | |||

Travel of tailstock quill | mm | 300 | 300 | 300 | 300 | |||

Taper hole of tailstock quill | - | Metric 80 | Metric 80 | Metric 80 | Metric 80 | |||

CNC System | - | FANUC | FANUC | FANUC or SIEMENS | FANUC | |||

Workpiece accuracy | - | IT7 | IT7 | IT7 | ||||

Surface roughness | µm | Ra2.5-3.2 | Ra2.5-3.2 | Ra2.5-3.2 | ||||

Main motor power | kw | 30 | 30 | 37 | 30 | |||

Machine weight | kg | 15000/19400/21560/26000/30400/34800 | ||||||

Length | mm | 6400/8400/9400/11400/13400/15400 | 6400/8400/9400/11400/13400/15400 | 6400/8400/9400/11400/13400/15400 | ||||

Width | mm | 3200 | 3200 | 3200 | ||||

Height | mm | 2220 | 2750 | 2850 | 2950 | |||

STANDARD ACCESSORIES: | OPTIONAL ACCESSORIES: |

FANUC/GSK/SIEMENS CNC system, 4-jaw chuck, 4-station electric tool-post, Work lamp, Cooling system, Manual pulse (MPG), Dead centers, Oil gun, Pilot lamp, Automatic lubrication pump, Electric moving tailstock, Tools & tool-box, Leveling wedge & bolts, Operation manual (English). | 6/8-station tool-post, Steady rest, Roller support, Full guard, Live centers, Air conditioner, Chip conveyor |

Why Choose Us

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product