High Precision 210mm Travel Slant Bed Cnc Lathe for Small and Medium-sized Parts

Product Details:

| Place of Origin: | China |

| Brand Name: | TIMAC |

| Model Number: | CK-32/CK-36/CK-45 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $35,000.00/sets 1-2 sets |

|

Detail Information |

|||

| Type: | Horizontal | Max. Length Of Workpiece (mm): | 210 |

|---|---|---|---|

| Structure: | Slant Bed Lathe | Machining Capacity: | Medium Duty |

| Max. Weight Of Workpiece(kg): | 500 | Width Of Bed (mm): | 200 Mm |

| No. Of Spindles: | Single | Number Of Axes: | 2 |

| Travel (X Axis)(mm): | 210 Mm | Travel (Z Axis)(mm): | 450 Mm |

| Positioning Accuracy (mm): | ±0.003 | Repeatability (X/Y/Z) (mm): | ±0.001 |

| Dimension(L*W*H): | 2600x1800x1600 | Voltage: | 220V/380V |

| CNC Control System: | Siemens | Tool Post Stations: | 8 |

| Weight (KG): | 2700 | Warranty: | 1 Year |

| Key Selling Points: | Multifunctional | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 1 Year |

| Range Of Spindle Speed(r.p.m): | 30 - 2500 R.p.m | Travel (Y Axis)(mm): | 500 Mm |

| Spindle Taper: | ISO40, BT40, ISO30, BT50 | Cutting Torque: | 2500 N.m |

| Rapid Feed Speed(mm/min): | 32 - 250 Mm/min | Feed Speed(mm/min): | 32 - 320 Mm/min |

| Min. Time Of Tool Change(s): | 0.7 | Max. Swing Over Bed: | 420 |

| Max. Swing Over Cross Slide: | 220 | Standard Turning Diameter: | 210 |

| Max.turning Diameter: | 320 | Max.turning Length: | 350 |

| Spindle Speed: | 3500 | Spindle Nose: | A2-5 |

| Spindle Bore: | 56 | Hydraulic Chuck Size: | 160 |

| Cross Travel (X): | 210 | ||

Product Description

Products Description

Features:

--This machine adopts 45° inclined layout, and the bed is tubular hollow structure, which greatly improves the bending and torsional rigidity of the machine during work. At the same time, after two aging treatments, the stability of the machine is improved, and the rigidity is high. --The high stability of the bed provides a powerful guarantee for the high precision of the whole machine.

--The spindle of the machine is an independent spindle unit. It is equipped with high-precision spindle special bearings. The lubrication uses imported special bearing grease (KLUBER). The whole spindle unit has small thermal deformation, good thermal stability, good precision retention and maintenance-free. The high-precision, high-rigidity, high-speed, high-efficiency of the spindle unit enables the whole machine to finish rough and finish machining.

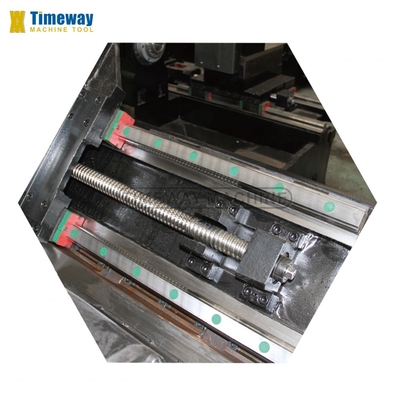

---The feed system is driven by the servo motor directly, with good rigidity and dynamic characteristics. The entire sliding surface is plasticized or lined to eliminate creep, greatly improve the working precision, complete precise movement and positioning, and increase wear resistance of

the moving parts of the machine, and enhance the impact resistance, so that the performance of the whole machine can maintain the accuracy of the guide rail for a long time and improve the service life of the machine.

---This machine is equipped with perfect rotary cylinder and three-jaw power chuck. The hydraulic system, hydraulic pump and various hydraulic valves are all famous brand products with high reliability.

---This machine adopts high-quality and reliable domestic or world-renowned numerical control system, advanced full-interchange digital servo, advanced electrical control system design, reasonable application of electrical components, and the failure rate is minimized in similar

products.

---This machine adopts a fully enclosed protective cover. The design of the protective cover is firm and reliable, and everything is safe and convenient for users.

---The tailstock sleeve is hydraulically driven, saving time and effort, and has a moving and positioning inter-turning device to prevent misoperation, providing users with safety guarantee during operation and use.

---This full-function CNC lathe is suitable for the processing of various shaft and disc parts with high precision requirements, high processing difficulty, many processes and mass production. At present, this machine has been widely used in motorcycle industry and the automobile manufacturing industry.

--The spindle of the machine is an independent spindle unit. It is equipped with high-precision spindle special bearings. The lubrication uses imported special bearing grease (KLUBER). The whole spindle unit has small thermal deformation, good thermal stability, good precision retention and maintenance-free. The high-precision, high-rigidity, high-speed, high-efficiency of the spindle unit enables the whole machine to finish rough and finish machining.

---The feed system is driven by the servo motor directly, with good rigidity and dynamic characteristics. The entire sliding surface is plasticized or lined to eliminate creep, greatly improve the working precision, complete precise movement and positioning, and increase wear resistance of

the moving parts of the machine, and enhance the impact resistance, so that the performance of the whole machine can maintain the accuracy of the guide rail for a long time and improve the service life of the machine.

---This machine is equipped with perfect rotary cylinder and three-jaw power chuck. The hydraulic system, hydraulic pump and various hydraulic valves are all famous brand products with high reliability.

---This machine adopts high-quality and reliable domestic or world-renowned numerical control system, advanced full-interchange digital servo, advanced electrical control system design, reasonable application of electrical components, and the failure rate is minimized in similar

products.

---This machine adopts a fully enclosed protective cover. The design of the protective cover is firm and reliable, and everything is safe and convenient for users.

---The tailstock sleeve is hydraulically driven, saving time and effort, and has a moving and positioning inter-turning device to prevent misoperation, providing users with safety guarantee during operation and use.

---This full-function CNC lathe is suitable for the processing of various shaft and disc parts with high precision requirements, high processing difficulty, many processes and mass production. At present, this machine has been widely used in motorcycle industry and the automobile manufacturing industry.

SPECIFICATION | UNIT | CK-32 | CK-36 | CK-45 | ||

Max. swing over bed | mm | 420 | 550 | 500 | ||

Max. swing over cross slide | mm | 220 | 220 | 220 | ||

Standard turning diameter | mm | 210 | 210 | 210 | ||

Max.turning diameter | mm | 320 | 360 | 360 | ||

Max.turning length | mm | 350 | 500 | 750 | ||

Spindle speed | rpm | 3500 | 3000 | 2500 | ||

Spindle nose | A2-5 | A2-6 | A2-6 | |||

Spindle bore | mm | 56 | 62 | 66 | ||

Hydraulic chuck size | mm | 160 | 200 | 200 | ||

Cross travel (X) | mm | 210 | 230 | 220 | ||

Longitudinal travel (Z) | mm | 450 | 600 | 850 | ||

X/Z-axis rapid feed speed | m/min | 20/12 | 24/24 | 20/20 | ||

Hydraulic cool post type | 80-8T | 80-8T | 80-8T | |||

Tool section size | mm | 25×25/32 | 25x25/32 | 25x25/32 | ||

Tailstock quill diameter | mm | 52 | 110 | 110 | ||

Tailstock quill travel | mm | 60 | 100 | 100 | ||

Tailstock quill taper | MT4 | MT5 | MT4 | |||

Bed structure | 45° Integral bec | 45° Integral bed | 45° Integral bed | |||

Guideway type | Linear/Sliding | Linear/Sliding | Linear/Sliding | |||

Main motor power | kw | 7.5 | 11 | 7.5 | ||

Power supply | kva | 30 | 25 | 30 | ||

Machine dimensions (LxWxH) | mm | 2600x1800x1600 | 2900x1800x1750 | 2900x1800x1600 | ||

Machine weight | kg | 2700 | 3200 | 3200 | ||

· FANUC 0i mate TD CNC system · 3 jaw chuck · 4 station electric tool post · Coolant system, Auto. Lubrication unit · Lighting unit · Manual moving tailstock · Semi-closed guard · General tools · Operator manuals (English edition)etc. | · 6 station electrical tool post; · Hydraulic solid chuck; · Hydraulic hollow chuck; · Hydraulic tailstock. |

Why Choose Us

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product