***This type slant bed CNC lathe is semi-closed loop CNC machine, which is suitable to turn various complicated shaft, sleeve and disk-like work pieces, such as turning of internal and external cylindrical, conical and other circumgyration surface as well as various metric, inch, modular and diametric pitch threads;

***They can also be used for oil grooves and keyways broaching, end-facing, grooving and chamfering, etc;

***The unique construction developed using FEA techniques to provide maximum stiffness under the heaviest cutting conditions;

***It is especially suitable for the machining of high precision work-pieces, and also widely used to machining parts in batches in the fields of automobile, motorcycle, engineer industry, aero-craft, home-appliance, bearing, hardware, etc

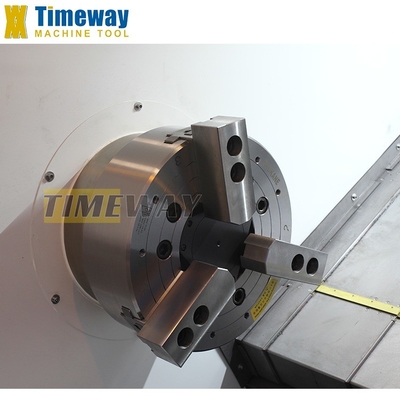

Medium Duty Machining Slant Bed CNC Lathe CK-80 with 380mm Chuck Size and FANUC System

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | Timeway/TIMAC |

| Model Number: | CK-80/1000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $60,000.00/sets 1-2 sets |

| Packaging Details: | Wooden cases(can be fumigated) |

| Supply Ability: | 150 Set/Sets per Month |

|

Detail Information |

|||

| Type: | Horizontal | Max. Length Of Workpiece (mm): | 3000 |

|---|---|---|---|

| Structure: | Slant Bed Lathe | Machining Capacity: | Medium Duty |

| Width Of Bed (mm): | 500 Mm | Spindle Motor Power(kW): | 22 |

| No. Of Spindles: | Single | Number Of Axes: | 2 |

| Travel (X Axis)(mm): | 400 Mm | Travel (Z Axis)(mm): | 1120 Mm |

| CNC Control System: | FANUC | Tool Post Stations: | 12, 8 |

| Weight (KG): | 5800 | Warranty: | 1 Year |

| Key Selling Points: | High Productivity | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 1 Year |

| Machine Type: | Cnc Slant Bed Lathe Machine | Max. Swing Over Bed: | 800mm |

| Max. Swing Over Cross Slide: | 640mm | Standard Turning Diameter: | 460mm |

| Max. Turning Diameter: | 660mm | Max. Turning Length: | 1000mm |

| Spindle Speed: | 1500rpm | Spindle Bore: | 112mm |

| Chuck Size: | 380mm | CNC Or Not: | CNC |

| Condition: | New | Applicable Industries: | Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Construction Works , Energy & Mining |

| Showroom Location: | Canada, Philippines, Brazil, Peru, Mexico, Russia, Thailand, Kenya, Chile, Romania, Japan | Core Components: | Bearing, Motor, PLC, Engine |

| Max. Spindle Speed (r.p.m): | 1500 R.p.m | Spindle Bore(mm): | 112 |

| Max. Turned Length (mm): | 1000 | Marketing Type: | Hot Product |

| Port: | China Port | ||

Product Description

Summary

1.The full-function CNC lathe has a semi-closed-loop control system that increases productivity through high-speed cutting. It issuitable for machining all kinds of complex shapes of shaft, sleeve, disk parts, especially for multi-species, a small batch of turning processing.

2.Easy clamping, process adaptability, high processing efficiency, low scrap rate, good consistency of the

finished product, and reducing the technical proficiency requirements of workers, easy programming, simple operation, which makes it is widely selected as the ideal small and medium-sized mechanical processing equipment.

finished product, and reducing the technical proficiency requirements of workers, easy programming, simple operation, which makes it is widely selected as the ideal small and medium-sized mechanical processing equipment.

3.The bed adopts the box-shaped structure, one-piece moulding casting technology, and 45-degree slant.

Product Description

Slant Bed CNC Lathe

Feature:

Specification

Specification | Unit | CK-80 |

Max. Swing over bed | mm | 800 |

Max. Swing over cross slide | mm | 640 |

Standard turning diameter | mm | 460 |

Max. Turning diameter | mm | 660 |

Max. Turning length | mm | 1000 |

Spindle speed | rpm | 1500 |

Spindle nose | - | A2-11 |

Spindle bore | mm | 112 |

Chuck size | mm | 380 |

Cross travel (X) | mm | 400 |

Longitudinal travel (Z) | mm | 1120 |

X/Z-axis rapid feed speed | m/min | 12/16 |

Hydraulic tool post type | - | 125-12T |

Tool section size | mm | 32×32 |

Tailstock quill diameter | mm | 150 |

Tailstock quill travel | mm | 150 |

Tailstock quill taper | - | MT5 |

Bed structure | - | 30° integral bed |

X-axis repositioning accuracy | mm | 0.008 |

Z-axis repositioning accuracy | mm | 0.01 |

Roughness | - | Ra1.6μm |

Main motor power | kw | 22 |

Power supply | kva | 50 |

Accessories

STANDARD ACCESSORIES:

* FANUC CNC system

* Hydraulic chuck

* 8/12-station tool turret

* Hydraulic tool post

* Electronic handwheel

* Lubrication system

* Cooling system

* Work lamp

* Pilot lamp

* Protection guard

* Heat exchanger

* Leveling blocks & bolts

* Tool & tool-box

* Operation manuals

OPTIONAL ACCESSORIES:

* GSK,SIEMENS CNC system

* Air conditioner

* Tool setter

* Chain type chip conveyor

Company Profile

Timeway Machine Tool Co., Ltd. is a professional machine tool manufacturing enterprises, the main products include lathe, milling machine, grinding machine, etc., and according to customer needs we also can design and manufacture various special purpose machines, to provide relative technology upgrading and transformation services in machine tool field.

Our company has advanced production testing equipment, first-class R & D, production, sales and service teams, and behave the own production and acceptance standard higher than the national standard to ensure that each machine delivered by us can make customer satisfaction and help customer create the greatest benefits.

Client feedback

Adhering to the "quality products, first-class service, sustainable development" concept, adhere to the "low-key life,high-profile work" spirit of enterprise, look forward to sincere cooperation and work together with the friends from domestic and abroad to create a better future for all.

FAQ

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A:(1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product