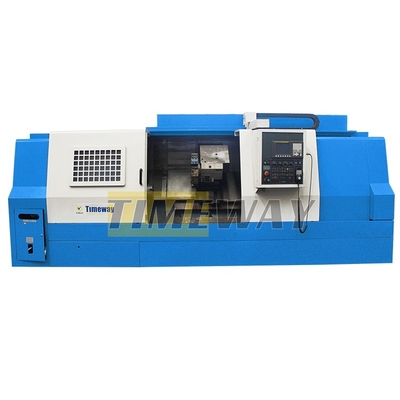

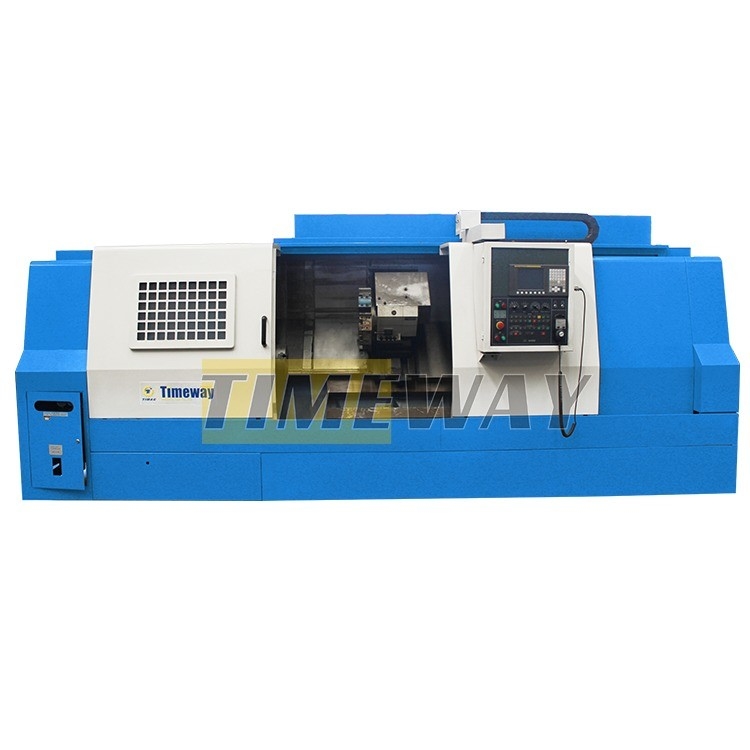

Medium Duty CNC Turning Center 590/965/1465/1965mm Z-axis Travel for Metal Machining

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | Timac |

| Model Number: | AK-25 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $53,000.00/sets 1-2 sets |

|

Detail Information |

|||

| Type: | Horizontal | Max. Length Of Workpiece (mm): | 3000 |

|---|---|---|---|

| Structure: | Slant Bed Lathe | Machining Capacity: | Medium Duty |

| Width Of Bed (mm): | 0 Mm | Spindle Motor Power(kW): | 30 |

| No. Of Spindles: | Twin | Number Of Axes: | 2 |

| Travel (X Axis)(mm): | 230 Mm | Travel (Z Axis)(mm): | 2965 Mm |

| Dimension(L*W*H): | 2270x1470x1650mm | Voltage: | 15/18.5kw |

| CNC Control System: | FANUC | Tool Post Stations: | 8 |

| Weight (KG): | 4500 | Warranty: | 1 Year |

| Key Selling Points: | Automatic | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 1 Year |

| Swing Over Bed: | 520mm | Max.turning Dia: | 420mm |

| Max.turning Dia Over Carriage: | 360mm | Max.turning Length: | 530/905/1405/1905mm |

| Distance Between Centers: | 625/1000/1500/2000mm | Max.bar Capacity: | 70mm |

| X-axis Travel: | 230mm | Z-axis Travel: | 590/965/1465/1965mm |

| Rapid Traverse(x-and Z-axis): | 12.0/15m/min | Cutting Feed(x-and Z-axis): | 5000mm/min |

| Applicable Industries: | Building Material Shops, Machinery Repair Shops, Manufacturing Plant | Showroom Location: | Canada, Italy, France, Russia |

| Marketing Type: | Ordinary Product | Core Components: | Motor, Pump |

| Max. Spindle Speed (r.p.m): | 3500 R.p.m | Spindle Bore(mm): | 87 |

| Max. Turned Length (mm): | 2905 | ||

Product Description

Product Description

The full-function CNC lathe has a semi-closed-loop control system that increases productivity through high-speed cutting. It is suitable for machining all kinds of complex shapes of shaft, sleeve, disk parts, such as turning inner and outer cylindrical surface, conical surface, circular surface, end face, slotted, chamfering, drilling, reaming, especially for multi-species, a small batch of turning processing. Easy clamping, process adaptability, high processing efficiency, low scrap rate, good consistency of the finished product, and reducing the technical proficiency requirements of workers, easy programming, simple operation, which makes it is widely selected as the ideal small and medium-sized mechanical processing equipment.

Specification

Specification | Unit | AK-25 | AK-35 |

Swing over bed | mm | 520 | 660 |

Max.turning dia | mm | 420 | 550 |

Max.turning dia over carriage | mm | 360 | 420 |

Max.turning length | mm | 530/905/1405/1905 | 780/1530/1890/2890 |

Distance between centers | mm | 625/1000/1500/2000 | 890/1640/2000/3000 |

Max.bar capacity | mm | 70 | 80 |

X-axis travel | mm | 230 | 305 |

Z-axis travel | mm | 590/965/1465/1965 | 855/1605/1965/2965 |

Rapid traverse(x-and z-axis) | m/min | 12.0/15 | 12.0/15 |

Cutting feed(x-and z-axis) | mm/min | 5000 | 5000 |

Hand feed(x-and z-axis) | mm/min | 1260 | 1260 |

Spindle speed | rpm | 35-3500 | 25-2500 |

Spindle nose | mm | A2-8 | A2-8 |

Size of chuck | inch | 10" | 12" |

Spindle front end bearing(dia) | mm | 130 | 160 |

Spindle bore(dia) | mm | 87 | 92 |

Number of stations | 12 | 12 | |

Indexing time | s | 1 | 1 |

Tool shank size | mm | 25×25 | 25×25 |

Boring bar shank dia | mm | 40 | 50 |

Main spindle motor | kw | 18.5/15 | 30/22 |

X-axis servo motor | kw | 1.6 | 3 |

Z-axis servo motor | kw | 3 | 4 |

Max travel of tailstock | mm | 490/865/1365/1865 | 760/1500/1900/2900 |

Tailstock quill dia | mm | 85 | 110 |

Tailstock travel | mm | 80 | 100 |

Tailstock quill taper hole | MT-5 | MT-5 | |

Power | kw | 30 | 46 |

Machine weight | kg | 5000/5500/6500/7500 | 8000/10000/11000/15000 |

Floor space | 3000/3380×1545, 4550×1630, 4960×1900 | 3620×1820, 4725×1840, 5825×1900, 7000×2200 | |

X-axis positioning accruacy R | mm | 0.01 | 0.01 |

X-axis positioning accruacy B | mm | 0.012 | 0.012 |

X-axis positioning accruacy A | mm | 0.025 | 0.025 |

Z-axis positioning accruacy R | mm | 0.007 | 0.007 |

Z-axis positioning accruacy B | mm | 0.006 | 0.006 |

Z-axis positioning accruacy A | mm | 0.016 | 0.016 |

Accessories

Standard accessories:

FANUC 0i TD CNC system,

Coolant system,

Hydraulic system,

Standard worklight,

Chip splash guard complete,

Operation light,

Hydraulic slide chuck,

Hydraulic slide chuck,

Drum type turret,

Manual tailstock,

C-axis function (M series),

Powered turret (M series),

Finger chuck (M series),

One set of tool kits,

Technical documents.

Optional accessories:

Chip conveyor,

Chip bucket,

Tool setter,

Hydraulic thru hole chuck,

Programming tailstock,

Automatic door,

Hydraulic steady rest.

Our Team

Timeway Machine Tool Co., Ltd. is a professional machine tool manufacturing enterprises, the main products include lathe, milling machine, grinding machine, etc., and according to customer needs we also can design and manufacture various special purpose machines, to provide relative technology upgrading and transformation services in machine tool field.

Our factory was established in 2014. It has professional technicians, a research and development team, manufactures and sells CNC equipment and provides professional customized services.Our products are widely used in mold processing, 3C products, agricultural machinery, petroleum machinery, auto parts processing, aerospace industry, etc., selling more than 60 countries and regions in domestic and abroad.

Why Choose Us

This is a picture of clients visiting our company when we hold exhibitions around the world.

This is the picture of the packaging in our factory!You can see our package is standardized and centralized , then they will be shipped to your designated place.

Positive Comments From Customers

This picture is the customer's favorable feedback to us. A picture can't mean anything, but we insist on the quality of the machine, we believe that repeat customers will be more and more.

FAQ

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product