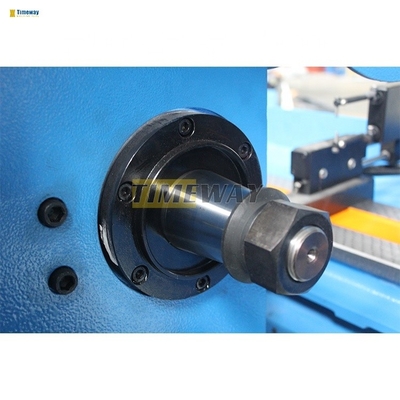

Grinding spindle with segmented high- precision bearings, adjustable and low maintenance. Grinding spindle adopts oil- bath lubration and coolant (N2 oil).

Workhead spindle speeds are infinitely variable and driven frequency motor and interver, can be easily adjusted and optimized during the machining process.

SIEMENS CNC System High Precision Grinding Machine 800mm Grinding Length 3000kg Weight

Product Details:

| Place of Origin: | China |

| Brand Name: | TIMEWAY |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $29,999.00/sets 1-2 sets |

| Packaging Details: | Wooden cases(can be fumigated) |

| Supply Ability: | 150 Set/Sets per Month |

|

Detail Information |

|||

| Grinding Diameter(Outer)(mm): | 200 | Grinding Length(mm): | 800 |

|---|---|---|---|

| Max. Length Of Workpiece (mm): | 850 | Max. Weight Of Workpiece(kg): | 50 |

| Center Height (mm): | 135 | Wheel Size(mm): | 400 |

| Wheel Speed (rpm): | 2130 | Roundness(mm): | 1.5 |

| Surface Roughness(μm): | 0.32 | Year: | 2022 |

| Voltage: | As Cunstomer's Required | Dimension(L*W*H): | 3000 X1600x1500mm |

| Weight (KG): | 3000 | Power (kW): | 10.825 |

| Key Selling Points: | Competitive Price | Warranty: | 1 Year |

| Showroom Location: | India, Indonesia, UAE, Germany, Mexico, France, Australia, Morocco, South Africa, Egypt, South Korea, Russia, Malaysia, Turkey, United States, Uzbekistan, Thailand, Peru, Italy, Ukraine, United Kingdom, Chile, Pakistan | Applicable Industries: | Manufacturing Plant, Energy & Mining, Construction Works |

| Marketing Type: | New Product 2019 | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 1 Year |

| Core Components: | Motor, Engine, Other | Condition: | New |

| CNC Or Not: | CNC | Diameter Of Grinding: | 8-200mm |

| Headstock Center: | MT4 | Tailstock Center: | MT4 |

| Grinding Wheel Size: | 400x50x203 | X-axis Min.feed Unit: | 0.001mm |

| Z-axis Min.feed Unit: | 0.001mm | Longitudinal Servo Motor Power: | 1.6kw |

| Cross Servo Motor Power: | 1.6kw | Type: | CNC |

| Loading Capacity: | 50kg | ||

Product Description

Products Description

* The CNC cylindrical grinder is suitable for batch production of cylindrical parts grinding with high performance to price ratio.

* The machine standard adopts German SIEMENS CNC system, and the executive system is driven by the CNC servo driver and servo motor. Worktable longitudinal travel (Z) and wheelhead cross travel (X) which with the high infeed accuracy are realized by the servo motors driven the ball screw transmission.

* The machine standard adopts German SIEMENS CNC system, and the executive system is driven by the CNC servo driver and servo motor. Worktable longitudinal travel (Z) and wheelhead cross travel (X) which with the high infeed accuracy are realized by the servo motors driven the ball screw transmission.

* With the SIEMENS CNC system programming and human-machine interface, simple and easy, and equipped with other CNC systems and configured online automatic measuring instruments for customers' choice.

* Simple and easy to operate for the grinder, after simple training, it can be operated easily. By setting the parameter of longitudinal grinding or plunge grinding by CNC control panel, an auto-grinding for the different workpiece is realized.

* This machine has automatic shifting of the table, which can automatically grind multiple steps of a workpiece. The multi-step can be arbitrarily arranged for longitudinal grinding and cutting into grinding sequence and grinding process parameters.

* CNC control system with the function of wheel dressing and compensation automatically.

* Wheelhead spindle is supported by three bushing hydro-dynamic bearing, and high precision hydro dynamic-static bearing is also available for the user.

* Timing provision of lubrication for machine moving parts according to program designing. Automatic lubrication of all moving parts. Tailstock has two ways:hydraulic and manual.

* Workhead spindle driven by variable frequency motor and frequency inverter, and programmed through M-code and S-code of CNC system for stepless speed.

* Workhead spindle driven by variable frequency motor and frequency inverter, and programmed through M-code and S-code of CNC system for stepless speed.

* Wheelhead swivel 180° for changing outside grinding and inside grinding. Optional full-closed guard.

Specification | Unit | GK-200H | UGK-200H |

Dia. ground (O.D) | mm | 8-200 | 8-200 |

Grinding length (O.D) | mm | 500/800 | 500/800 |

Center height | mm | 135 | 135 |

Distance between centers | mm | 550/850 | 550/850 |

Headstock center | - | MT4 | MT4 |

Tailstock center | - | MT4 | MT4 |

Loading capacity | kg | 50 | 50 |

Grinding wheel size | mm | Ф400x50xФ203 | Ф400x50xФ203 |

Max. peripheral speed of grinding wheel | m/s | 38 (hydrodynamic-hydrostatic 45m/s) | 38 (hydrodynamic-hydrostatic 45m/s) |

Grinding spindle speed | rpm | 2130 | 2130 |

Internal grinding spindle speed | rpm | - | 16000 |

Dia. ground (I.D) | mm | - | 13-100 |

X-axis min. feed unit | mm | 0.001 | 0.001 |

Z-axis min. feed unit | mm | 0.001 | 0.001 |

Total power | kw | 10.825 | 10.825 |

Longitudinal servo motor power | kw | 1.6 (6N.m) | 1.6 (6N.m) |

Cross servo motor power | kw | 1.6 (6N.m) | 1.6 (6N.m) |

Roundness | um | 1.5 | 1.5 |

Roughness | um | Ra0.32 | Ra0.32 |

Unifomity of dia.in longitudinal section | um | 5 | 5 |

· Grinding wheel, · Grinding wheel flange, · Three jaw chuck (UG), · Driving dog, ·Arbor for internal grinding (UG), · Grinding wheel dresser, · Wheel balancing arbor, · Open type steady rest, · Dead centers, · Frequency inverter, · Coolant system, · Work lamp, · Leveling wedge, · Operation manual (English edition). | · Wheel balancing stand · Radius dresser · Close type center rest · Digital readout · Paper filter · Magnetic separator |

Table can swivel certain angle for grinding conical cylinder.

Standard tailstock can opearte either manual by handle or hydraulic control by foot pedal, sometime hand wheel on the end of tailstock can adjustable clamping force.

External grinding for rotating part

Grinding head can be rotated 180° to change from inside to outside grinding.

With the SIEMENS CNC system programming and human-machine interface, simple and easy, and equipped with other CNC systems and configured online automatic measuring instruments for customers'choice.

Why Choose Us

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product