Our factory was established in 2014. It has professional technicians, a research and development team, manufactures and sells CNC equipment and provides professional customized services.Our products are widely used in mold processing, 3C products, agricultural machinery, petroleum machinery, auto parts processing, aerospace industry, etc., selling more than 60 countries and regions in domestic and abroad.

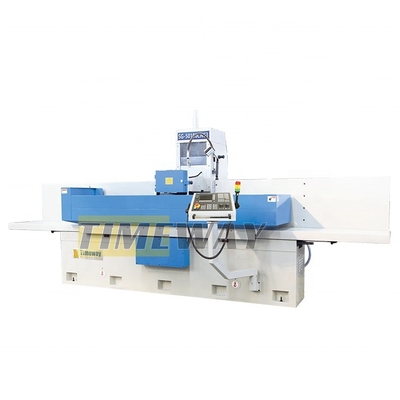

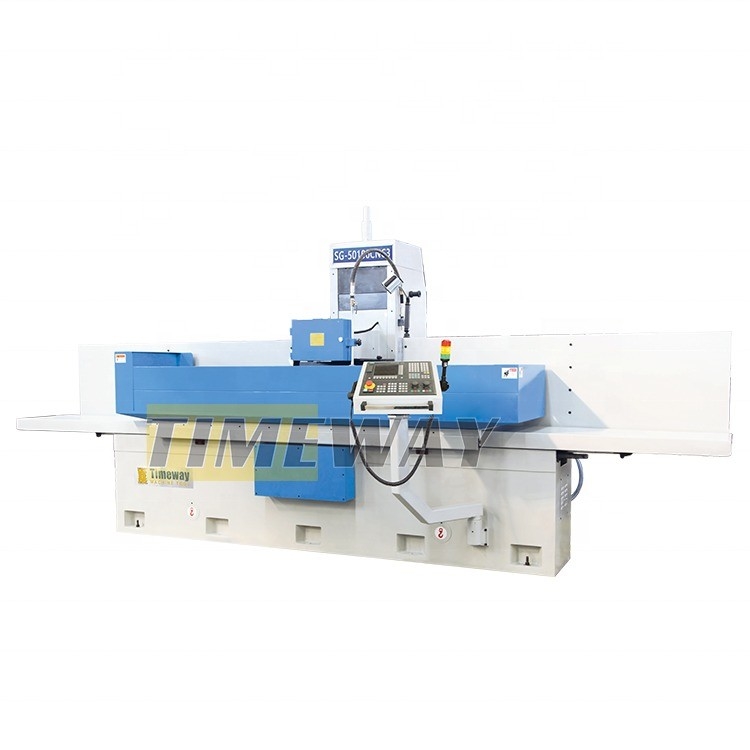

High Speed Surface Grinding Machine in with 1000mm Grinding Length and Column Moving Type

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | TIMAC |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $20,000.00/sets 1-2 sets |

|

Detail Information |

|||

| Condition: | New | Grinding Length(mm): | 1000 |

|---|---|---|---|

| Surface Roughness(μm): | 0 μm | Table Size(mm): | 500*1000mm |

| Table Travel (X) (mm): | 500 | Table Travel (Y) (mm): | 1000 |

| Dimension(L*W*H): | 3990*2250*2500mm | Weight (KG): | 5500 |

| Power (kW): | 7.5 | Warranty: | 1 Year |

| Key Selling Points: | Automatic | Showroom Location: | France, Japan, Russia |

| Marketing Type: | Ordinary Product | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 1 Year |

| Core Components: | Motor | Applicable Industries: | Manufacturing Plant |

| Table Size: | 500x1000mm | Grinding Area: | 500x1000mm |

| Distance From Spindle To Table: | 600mm | Electro Magnetic Chuck Size (pcs.): | 500x1000x1mm |

| Table Longitudinal Feed Speed: | 5-25m/min | Cross Intermittent Feed Rate: | 0-30mm/str |

| Cross Continuous Feed Speed: | 0-600mm/min | Cross Feed Rate (MPG): | 0.005mm/gra |

| Vertical Intermittent Feed Rate: | 0.005/0.01/0.02/0.03/0.04mm/str | Vertical Continuous Feed Speed: | 0-300mm/min |

Product Description

Product Description

Column Moving Type Surface Grinder: SG-50100FR. SG-50160FR, SG-50450FR

Features:

* Independent hydraulic unit with air-cooling unit ensures low temperature rising and supply stable power for precision grinding. * With auto. center lubrication unit.

* Very easy to set auto ground program include rough, finish, and spark-out stroke.

* Precision grinding spindle runs in maintance-free, support by preload high precision angular ball bearing.

* The machine is designed for continuous operating at maximum speed, very quiet operation, maximum accuracy.

* MPG is equipped for Y&Z axis(spindle elevating and cross feed), the operating position is free, it is so easy to control the

machine.

* The machine is standard equipped with SIEMENS 7" LCD-TFT colourful touchable screen. Built in program of our engineers' genius philosophy makes the operation very simple and convenient for the operators.

* The machine bed, table and column are high grade casting iron, which supply strong base of grinding, the slideway is coated with TF wearable material and manual precision scrapped.

* Well designed external hydraulic unit, with high power oil pump and precision elec-magnetic valve set, stand equipped with cooling fan. The whole system supply great smoothly power for fine ground.

* Precision grinding spindle runs in maintance-free, support by preload high precision angular ball bearing.

* The machine is designed for continuous operating at maximum speed, very quiet operation, maximum accuracy.

* MPG is equipped for Y&Z axis(spindle elevating and cross feed), the operating position is free, it is so easy to control the

machine.

* The machine is standard equipped with SIEMENS 7" LCD-TFT colourful touchable screen. Built in program of our engineers' genius philosophy makes the operation very simple and convenient for the operators.

* The machine bed, table and column are high grade casting iron, which supply strong base of grinding, the slideway is coated with TF wearable material and manual precision scrapped.

* Well designed external hydraulic unit, with high power oil pump and precision elec-magnetic valve set, stand equipped with cooling fan. The whole system supply great smoothly power for fine ground.

Specification

Specification | Unit | SG-50100FR | SG-50160FR | SG-50450FR |

Table size | mm | 500x1000 | 500x1600 | 500x4500 |

Grinding area | mm | 500x1000 | 500x1600 | 500x4500 |

Distance from spindle to table | mm | 600 | 600 | 600 |

Electro magnetic chuck size (pcs.) | mm | 500x1000x1 | 500x800x2 | 500x1000x4 |

Table longitudinal feed speed | m/min | 5-25 | 5-25 | 5-25 |

Cross intermittent feed rate | mm/str | 0-30 | 0-30 | 0-30 |

Cross continuous feed speed | mm/min | 0-600 | 0-600 | 0-600 |

Cross feed rate (MPG) | mm/gra | 0.005 | 0.005 | 0.005 |

Vertical intermittent feed rate | mm/str | 0.005/0.01/0.02/0.03/0.04 | 0.005/0.01/0.02/0.03/0.04 | 0.005/0.01/0.02/0.03/0.04 |

Vertical continuous feed speed | mm/min | 0-300 | 0-300 | 0-300 |

Vertical feed rate (MPG) | mm/gra | 0.005 | 0.005 | 0.005 |

Grinding wheel size | mm | Φ355x(20-50)xΦ127 | Φ355x(20-50)xΦ127 | Φ355x(20-50)xΦ127 |

Main motor power | kw | 7.5 | 7.5 | 11 |

Package dimensions (LxWxH) | mm | 3990x2250x2500 | 5640x2250x2500 | 11500x2380x2500 |

Machine weight | kg | 5500 | 6000 | 14500 |

Accessories

Standard accessories:

- LC+SMART auto. grinding controller

- Coolant tank

- Work lamp

- Balancing arbor

- Wheel flange and extractor

- Wheel dresser stand

- Y/Z axis electrical wheel(MPG)

- Operation manual (English edition)

- Splashing guard

- Standard grinding wheel

- Leveling wedge and boltd

- Tools & tool-box

- Operation manual(English edition)

- Coolant tank

- Work lamp

- Balancing arbor

- Wheel flange and extractor

- Wheel dresser stand

- Y/Z axis electrical wheel(MPG)

- Operation manual (English edition)

- Splashing guard

- Standard grinding wheel

- Leveling wedge and boltd

- Tools & tool-box

- Operation manual(English edition)

Optional accessories:

- Balancing stand

- Magnetic separator

- Paper filter

- Oil tank guard

- Electrical magnetic chuck

- Built-in magnetic chuck controller

- Parallel wheel dresser - 2 axis digital readout

- Extra wheel flange

- Magnetic separator

- Paper filter

- Oil tank guard

- Electrical magnetic chuck

- Built-in magnetic chuck controller

- Parallel wheel dresser - 2 axis digital readout

- Extra wheel flange

Packing & Delivery

This is the picture of the packaging in our factory!You can see our package is standardized and centralized , then they will be shipped to your designated place.

Company Introduction

Since our company established, we have obtained many certificates. The above picture is for your reference. We will continue to provide excellent machine tools for domestic and foreign users.

Factory Display:

Text Introduction:

Company Profile:

Timeway Machine Tool Co., Ltd. is a professional machine tool manufacturing enterprises, the main products include lathe, milling machine, grinding machine, etc., and according to customer needs we also can design and manufacture various special purpose machines, to provide relative technology upgrading and transformation services in machine tool field.

FAQ

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price; 2 . Professional R&D team and 25 years export experience; 3 . Exported more than 60 countries; 4 . CE, ISO Certificates; 5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager); 6 . 12 months quality warranty; 7 . Oversea engineers available for problem resolving; Q: Do you have QC or any safety standards for your machinery? A: yes, we have established a highly strict quality control department to guanrantee good quality. Q: What's the MOQ? A: 1 set (Only some low cost machines will be more than 1 set ) Q: What about the payment terms? A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment; (2) Irrevocable LC at sight; (3) Western Union, MoneyGram, etc. Q: How about the warranty? A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product