3900 KG Weight 3725x1473x1622 mm Hot Engine Lathe Metal Turning Machine for Thread Cutting

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | TIMAC |

| Model Number: | AL-800Bx1500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $25,000.00/sets 1-2 sets |

| Packaging Details: | wooden case |

| Supply Ability: | 300 Set/Sets per Month . |

|

Detail Information |

|||

| Max. Length Of Workpiece (mm): | 1500 | Range Of Spindle Speed(r.p.m): | 6 - 800 R.p.m |

|---|---|---|---|

| Machining Capacity: | Heavy Duty | Width Of Bed (mm): | 550 |

| Type: | Horizontal | Spindle Motor Power(kW): | 11 |

| Voltage: | 220V/380V/400V/415V/440V/460V | Dimension(L*W*H): | 3725x1473x1622 Mm |

| Weight (KG): | 3900 KG | Warranty: | 1 Year |

| Key Selling Points: | High-accuracy | Marketing Type: | Ordinary Product |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | CNC Or Not: | Normal |

| Automatic Grade: | Semi-automatic | Color: | As Order |

| Max. Turning Diameter: | 800mm | Max. Turning Diameter Over Gap: | 1000mm |

| Gap Length: | 300mm | Max. Workpiece Weight: | 2000kg |

| Z-axis Leadscrew Pitch: | 12mm | Threads Kind: | Metric, Inch, Module, Diametrical |

| Guideway Type: | V-flat Type | Condition: | New |

| Spindle Bore(mm): | 100 | Applicable Industries: | Building Material Shops, Machinery Repair Shops, Manufacturing Plant |

| Showroom Location: | Canada, United Kingdom, United States, Italy, France, Germany, Russia, Australia | Core Components: | Bearing, Pump, Gear, Motor, Gearbox, Pressure Vessel |

| Max. Turned Length (mm): | 1350 Mm | Year: | 2021 |

| Port: | China Port | ||

Product Description

| 2021 Hot China Engine Lathe Metal Turning Machine

∴ AL-800Bx1500 ∴

|

![]()

| Actual testing : |

| Cutting external surface: | ||

|

|

|

|

| Cutting end surface: | |

|

|

|

| Standard accessories:

| Optional accessaries: |

|

|

|

| Technical parameter: |

| Item | Unit | AL-630B | AL-800B | AL-940B | |

| Capacities | Swing over bed | mm | 630 | 800 | 940 |

| Swing over carriage | mm | 350 | 520 | 660 | |

| Max. length of workpiece | mm | 750, 1000, 1500, 2000, 3000, 4000, 5000, 6000, 7000, 9000, 10000, - | |||

| Max. turning length | mm | 600, 850, 1350, 1850, 2850, 3850, 4850, 5850, 6850, 8850, 9850, - | |||

| Span of guideway | mm | 550 | 550 | 550 | |

| Spindle | Spindle nose |

| C11 | ||

| Spindle hole | mm | 110 | |||

| Taper hole of spindle |

| 1:20/120 | |||

| Range of spindle speeds | r/min | 7.5~1000 | 6~800 | 6~800 | |

| Number of spindle speeds |

| 18kinds | |||

| Feed motion | Longitudinal and cross | r/min | 64; 0.1~24.32 | ||

| Cross-to-longitudinal feed rate |

| 1/2 | |||

| Screw pitch of leadscrew | mm | 12 | |||

| Number and range of metric thread | mm | 50; 1~240mm | |||

| Number and range of inch thread | T.P.I | 26; 14~1 | |||

| Number and range of module thread | mm | 53; 0.5~120mm | |||

| Number and range of diametrical pitch thread | T.P.I | 24; 28~1 | |||

| Rapid traverse speed of carriage | mm/min | 4000 | |||

|

| Max. travel of cross slide | mm | 440 | 540 | 570 |

| Max. travel of top slide | mm | 200 | |||

| Section of tool shank | mm | 32 | |||

| Tailstock | Diameter of tailstock quill | mm | 100 | ||

| Travel of tailstock quill | mm | 250 | |||

| Taper hole of tailstock quill |

| Morse 5 | |||

| Other | Main motor power | kw | 11 | ||

| Machine mass | kg | 3200, 3400, 3700, 4200, 4700, 5800, 6800, 7800, 8800, 10800, 11800, - | 3400, 3600, 3900, 4400, 4900, 6000, 7000, 8000, 9000, 11000, 12000, - | 3900, 4100, 4400, 4900, 5400, 6500, 7500, 8500, 9500, 11500, 12500, - | |

| Machine overall dimension | Length | mm | 2958, 3275, 3725, 4225, 5225, 6275, 7355, 8355, 9275, 11275, 12275,- | ||

| Width | mm | 1393 | 1437 | 1430 | |

| Height | mm | 1537 | 1622 | 1690 | |

| Features: |

- These engine lathe are suitable mainly for turning internal and external cylindrical, conical and other swing surfaces as well as various metric, inch module and diametric pitch threads. They can also be used for broaching oil grooves and keyways.

- The side wall of bed is constructed with double-rib plates, and the shape of internal ribs is of box type and bevel ribs combination.

- On apron, there is a device operated by a single lever, used for rapid traverse of the carriage.

- Spindle’s braking and rotating direction change is controllled by hydraulic system, or by hand operation according to your choice.

- The saddle guideway is glued by “TSF” soft belt wear resisting materials.

- We can equip with automatic feeding mechanism for the power lathe.

- The top slid can be used independently for turning short cone, or in combination with longitudinal feeding turing long taper surface.

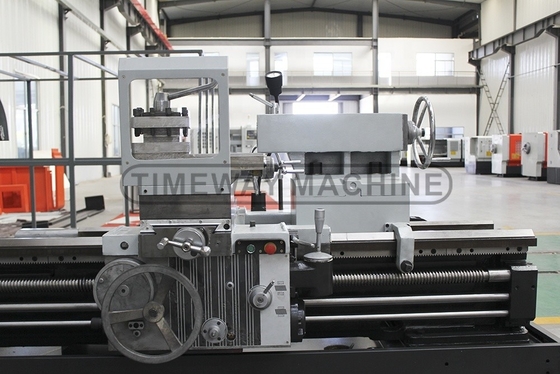

| Machine details: |

| 3-jaw chuck:

C11 spindle nose for connecting quickly 3-jaw or 4-jaw chuck. Optional chuck guard for the safety of the operators. | |

| Headsotck:

18steps spindle speed for meeting various kinds of processing requiremnts.

| |

| Carriage & tailstock:

All sliding surfaces are scraped by manual, the gap less than 0.04mm, in order to make sure machine accuracy and smooth moving. | |

| Gap (optional):

The gap bed lathe is equipped with a detachable gap to machining large diameter disc parts. | |

| 4-staitions tool post:

Manual 4-staitions tool post is standard, high positioning accuracy. The safety guard of the tool post comes optional. | |

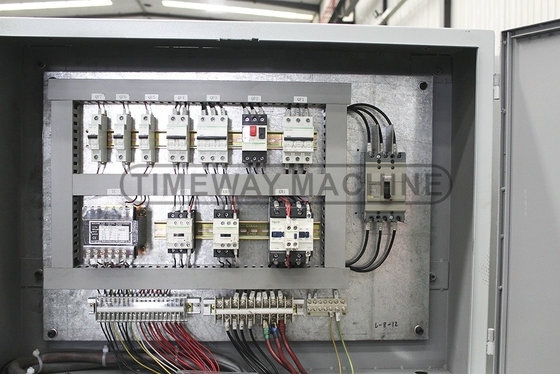

| CE-norm eclectrical cabinet:

Adopt Schneider electrical components, high stability and reliable action. |

| Finished machine: |

![]()

![]()

![]()

![]()

| Ready for shipment: |

![]()

![]()

![]()

![]()

![]()

| Why choose TIMEWAY MACHINE? |

![]()