>> Chuck guard for protecting operator is optional.

Metal Turning 410mm Swing Horizontal Lathe Machine Tool at with and 0.01mm Roundness

Product Details:

| Place of Origin: | China |

| Brand Name: | Timeway |

| Model Number: | CL-410/1500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $13,000.00/sets 1-2 sets |

| Packaging Details: | Wooden case/Pallet |

| Supply Ability: | 300 Set/Sets per Month |

|

Detail Information |

|||

| Max. Length Of Workpiece (mm): | 1500 | Range Of Spindle Speed(r.p.m): | 25 - 2000 R.p.m |

|---|---|---|---|

| Machining Capacity: | Light Duty | Width Of Bed (mm): | 300 |

| Type: | Horizontal | Spindle Motor Power(kW): | 5.5 |

| Voltage: | 200V-480V | Dimension(L*W*H): | 2750x1080x1340mm |

| Weight (KG): | 1745 KG | Warranty: | 1 Year |

| Key Selling Points: | Flexible Manufacturing | Marketing Type: | Hot Product 2021 |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Machine Type: | Small Parallel Flat Bed Lathe Machine | Turning Material: | Metal |

| Power Cable: | 3-phase & 4-wires System | Power Capacity: | 7 KVA |

| Lathe Using Oil: | 32# Or 46# Oil | Lathe Foundation: | More Depth 200mm Concrete |

| Working Accuracy: | IT6 | Roundness: | 0.01mm |

| Roughness: | Ra2um | Condition: | New |

| Spindle Bore(mm): | 58 | Applicable Industries: | Building Material Shops, Machinery Repair Shops, Food & Beverage Factory, Home Use, Energy & Mining |

| Showroom Location: | Italy, France, Germany, Brazil, Mexico, Russia, Spain, Romania, Ukraine, Uzbekistan, Australia | Core Components: | Bearing, Gear, Motor |

| Max. Turned Length (mm): | 1850 Mm | Year: | 2021 |

| Port: | China Ports | ||

Product Description

Products Description

3-jaw chuck | Living center |

4-jaw chuck | Taper turning attachment |

Face plate | Drill chuck |

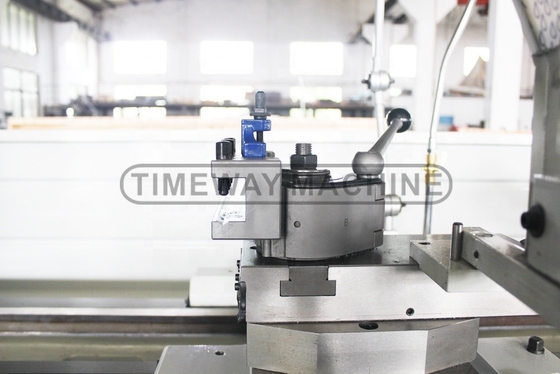

Dead centers | Quick change tool holder |

Thread chasing dial | 2/3 axis digital readout |

Splash guard | Chuck cover |

Oil gun | Leadscrew cover |

Work lamp | Tool post cover |

Cooling system | Driving plate |

Steady rest | |

Follow rest | |

Change gears | |

Reducing sleeve | |

Foot brake | |

Foundation bolts | |

Tool-box & tools | |

Operation manual |

Specification | Unit | CL-410 | CL-460 |

Max. swing over bed | mm | 410 | 460 |

Max. swing over cross slide | mm | 220 | 270 |

Max. swing over gap | mm | 640 | 690 |

Distance between centers | mm | 1000/1500/ 2000 | 1000/1500/ 2000 |

Gap length | mm | 165 | 165 |

Bed width | mm | 300 | 300 |

Spindle nose | - | D1-6 | D1-6 |

Spindle bore | mm | 58 | 58 |

Spindle taper | - | MT6 | MT6 |

Spindle speed range (steps) | rpm | 25-2000 (12) | 25-2000 (12) |

Top slide travel | mm | 128 | 128 |

Cross slide travel | mm | 285 | 285 |

Tool section size | mm | 25x25 | 25x25 |

Leadscrew | - | 40x4T.P.I or pitch 6mm | 40x4T.P.I or pitch 6mm |

Longitudinal feed range | mm/rev | 0.031-1.7 (42) | 0.031-1.7 (42) |

Cross feed range | mm/rev | 0.014-0.784 (42) | 0.014-0.784 (42) |

Metric threads range (kinds) | mm | 0.1-14 (41) | 0.1-14 (41) |

Inch threads range (kinds) | TPI | 2-112 (60) | 2-112 (60) |

Diametrical threads range (kinds) | DP | 4-112 (50) | 4-112 (50) |

Module threads range (kinds) | MP | 0.1-7 (34) | 0.1-7 (34) |

Tailstock quill diameter | mm | 60 | 60 |

Tailstock quill travel | mm | 130 | 130 |

Tailstock quill taper | - | MT4 | MT4 |

Main motor power | kw | 5.5 | 5.5 |

Coolant pump power | kw | 0.1 | 0.1 |

Machine dimensions (LxWxH) | cm | 220/275/325x108x134 | 220/275/325x108x137 |

Packing size (LxWxH) | cm | 225/280/330x112x162 | 225/280/330x112x162 |

Net weight | kg | 1580/1745/1900 | 1645/1810/1965 |

Gross weight | kg | 1844/2049/2229 | 1910/2115/2295 |

Machine Details

Machine features:

This series universal center lathe is a fantastic model for small to medium size turning works. Even its basic configuration includes important accessories, such as 3-jaw chuck, steady and follow rest, change gears etc. Increasing the application area of this model significantly. For reducing the non-productive time, this model is also can equipped with 2 or 3 axis digital readout.

Inductive hardened, polished grey cast-iron machine bed.

Electro mechanical foot brake reduces downtime significantly.

State-of-the-art main spindle bearing with high quality angular ball bearings.

Easy, smooth and precisely adjustable speed and feed settings.

Hardened, polished gears and shafts, also in feed gear unit.

Centrally located, logical switches for feeds and threads with leadscrew and feed rod.

Adjustable tailstock for taper turning, handwheel feature adjustable scale(0.02mm).

The removeable bridge allows machining of workpieces with a big diameter.

Head stock gears are made of high quality steel ground and hardened more than HRC 50.

===================================

>> 3-jaw manual chuck comes standard;

===================================

>> The lathe rails are hardened and ground;

>> Finish X and Z-axis automatic feeding;

>> Tool post guard is optional.

===================================

>> The steady rest and follow rest come standard for gap lathe machine.

===================================

>> Standard 4-station tool post, USA-type quick change tool post is available.

===================================

>> 2 & 3-axis DRO is optional;

>> Foot brake can realize quickly stopping the spindle;

>> Z-axis screw guard and sizing device come optional.

Test - roundness & cylindricity:

Precision turning the external surface of the bar, test accuracy:

Roundness: less than 0.01mm;

Cylindricity: less than 0.025/300mm

Test - verticality:

Precision turning the end surface of the disc, test accuracy:

Verticality: less than 0.02/300mm

Test - roughness:

Precision turning the external surface of the bar, test accuracy: Roughness: Ra1.6um

Threads turning test:

Fine turning taper threads (Taper: 1:16, Thread pitch: 3.175mm), after testing by special measuring device, it can meet accumulative error of pitch to 0.015/25.4mm.

Comprehensive testing parts (only for CNC horizontal lathe):

All CNC lathes must make a final cutting process after all standard inspections of the machine, through cutting external surface, steps, arc surface, tapered surface, etc., in order to inspect stability of CNC system and overall performance of the machine.

Why Choose Us

Renishaw laser interferometer (only for CNC horizontal lathe):

Before the delivery, it adopts UK RENISHAW laser to do dynamic precision testing and offset, so the machine has the high positioning accuracy and re-positioning accuracy.

Company Introduction

Want to Know more details about this product