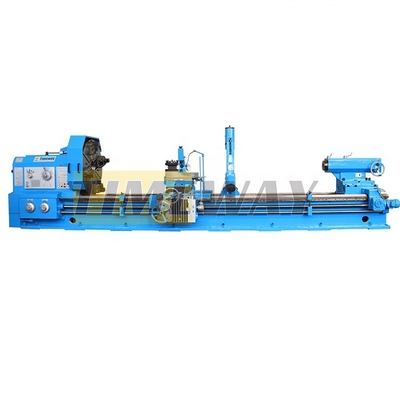

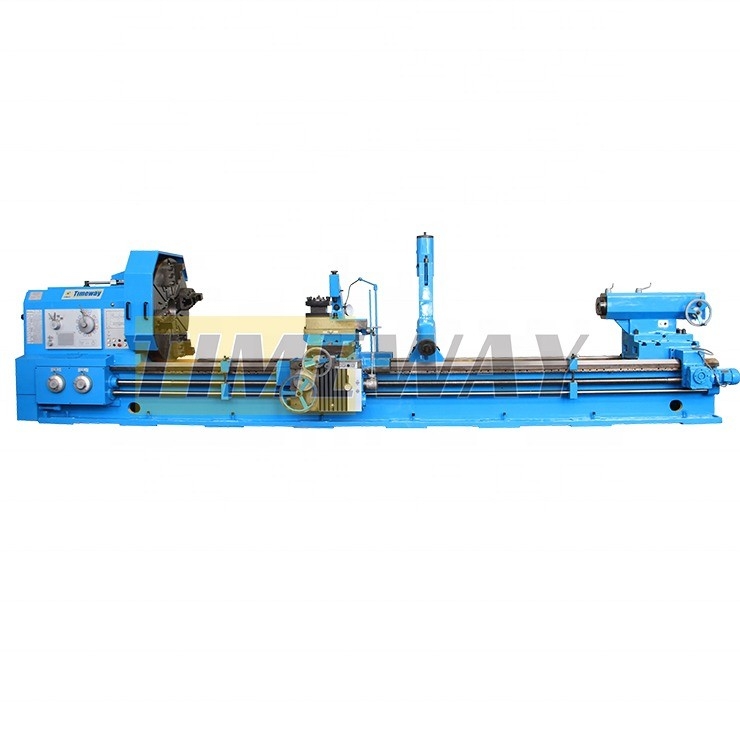

Stepless Spindle Speed Heavy-duty Turning Machine for Precision Machining Applications

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | TIMAC |

| Model Number: | AL-1600Hx5000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $300,000.00/sets 1-2 sets |

| Packaging Details: | wooden case(can be fumigated) |

| Supply Ability: | 5 Set/Sets per Month |

|

Detail Information |

|||

| Max. Length Of Workpiece (mm): | 5000 | Range Of Spindle Speed(r.p.m): | 0.8 - 160 R.p.m |

|---|---|---|---|

| Machining Capacity: | Heavy Duty | Width Of Bed (mm): | 1600 |

| Type: | Horizontal | Spindle Motor Power(kW): | 75 |

| Voltage: | 220V-460V | Dimension(L*W*H): | 15577x2479x2280mm |

| Weight (KG): | 28000 KG | Warranty: | 1 Year |

| Key Selling Points: | High-accuracy | Marketing Type: | New Product 2020 |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | CNC Or Not: | Normal |

| Automatic Grade: | Semi-automatic | Spindle Speed Steps: | Stepless |

| Color: | Blue-white Or Others | Max. Swing Diameter: | 1600mm |

| Chuck Diameter: | 1600mm | Loading Capacity: | 25/32/40tons |

| Working Accuracy: | IT6 | Roundness: | 0.01mm |

| Spindle Bore: | 75mm | Condition: | New |

| Applicable Industries: | Hotels, Garment Shops, Building Material Shops, Machinery Repair Shops, Manufacturing Plant, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Construction Works , Energy & Mining, Food & Beverage Shops, Advertising Company | Showroom Location: | Canada, United States, Italy, Germany, Mexico, Spain, Romania, South Africa, Australia |

| Core Components: | Bearing, Pump, Gear, Motor, Gearbox, Pressure Vessel | Spindle Bore(mm): | 75 |

| Max. Turned Length (mm): | 4800 Mm | Year: | 2021 |

| Port: | China Port | ||

Product Description

Products Description

Features:

This parallel turning machine is a universal lathe with loading capacity of 25/32/40 tons,

after used roller support and steady rest, loading capacity to be 40tons. It is suitable for high-speed steel and hard alloy steel tools. For shaft parts of different materials, cylindrical and disc-shaped parts, turning outer ring, end face, slotting, cutting, The boring, the inner and outer cones of the rut, and the use of the upper tool holder (via the hanging wheel) for turning various

threads of less than 600 mm in length.

1.The lathe bed is integral box-shaped three rectangular rail structure, which is cast in one-time casting with high-grade cast iron (HT300). After two times of aging treatment, the stability is good; the width of the guide rail is 1600mm, the rigidity is

good, and the anti-vibration capability is strong; Precision grinding by imported guide grinding machines ensures long life, high precision and good retention.

2. The main drive mechanism of the machine tool is driven by a 75KW DC motor. The total speed ratio of the variable speed control mode is 1:22.2, 3steps speed changing, and the mechanical and electrical speed ratio is 1:200. The spindle obtains a stepless speed regulation range of 0.8 to 160 r/min.

3.The feed system is connected to the main drive through the light bar, so that the feed is directly related to the spindle speed, and the feed rate is convenient to select.

4.The tailstock quill is a rotatable structure, which reduces the wear and heat of the centers.

5.The parallel turning machine standard equipped with electric moving tailstock, reduce operator labor intensity and improve work efficiency.

6.The parallel turning machine supply two kinds of center frame, that is a closed center frame and an open center frame.

7.Two rows of high-precision racks are installed on front and behind the machine, the front racks drives the carriage feed to realize turning thread, and the rear row of racks drives the tailstock for motorized movement.

8.High rigidity and high precision spindle: The machine tool spindle bearing adopts domestic famous brand products. The spindle box adopts a symmetrical structure to make the thermal deformation uniform and avoid the offset of the center of the spindle. To reduce thermal deformation, the headstock is lubricated with an oil bath cycle. The gears in the headstock are quenched and grounded to ensure accurate transmission and low noise. The well-assembled spindle has the characteristics of low temperature rise, small thermal deformation and high precision, which makes the spindle maintain relatively stable accuracy during long-term operation.

after used roller support and steady rest, loading capacity to be 40tons. It is suitable for high-speed steel and hard alloy steel tools. For shaft parts of different materials, cylindrical and disc-shaped parts, turning outer ring, end face, slotting, cutting, The boring, the inner and outer cones of the rut, and the use of the upper tool holder (via the hanging wheel) for turning various

threads of less than 600 mm in length.

1.The lathe bed is integral box-shaped three rectangular rail structure, which is cast in one-time casting with high-grade cast iron (HT300). After two times of aging treatment, the stability is good; the width of the guide rail is 1600mm, the rigidity is

good, and the anti-vibration capability is strong; Precision grinding by imported guide grinding machines ensures long life, high precision and good retention.

2. The main drive mechanism of the machine tool is driven by a 75KW DC motor. The total speed ratio of the variable speed control mode is 1:22.2, 3steps speed changing, and the mechanical and electrical speed ratio is 1:200. The spindle obtains a stepless speed regulation range of 0.8 to 160 r/min.

3.The feed system is connected to the main drive through the light bar, so that the feed is directly related to the spindle speed, and the feed rate is convenient to select.

4.The tailstock quill is a rotatable structure, which reduces the wear and heat of the centers.

5.The parallel turning machine standard equipped with electric moving tailstock, reduce operator labor intensity and improve work efficiency.

6.The parallel turning machine supply two kinds of center frame, that is a closed center frame and an open center frame.

7.Two rows of high-precision racks are installed on front and behind the machine, the front racks drives the carriage feed to realize turning thread, and the rear row of racks drives the tailstock for motorized movement.

8.High rigidity and high precision spindle: The machine tool spindle bearing adopts domestic famous brand products. The spindle box adopts a symmetrical structure to make the thermal deformation uniform and avoid the offset of the center of the spindle. To reduce thermal deformation, the headstock is lubricated with an oil bath cycle. The gears in the headstock are quenched and grounded to ensure accurate transmission and low noise. The well-assembled spindle has the characteristics of low temperature rise, small thermal deformation and high precision, which makes the spindle maintain relatively stable accuracy during long-term operation.

· 4-jaw heavy duty independent chuck · Steady rest (over 3M length) · Follow rest (over 3M length) · Electric moving tailstock · Dead center of tailstock · 4-station tool post · Cooling system · Work lamp · Tools & tool-box · Leveling wedge and bolts Operation manual (English) | · 2 or 3-axis digital indicator · Chuck guard · Tool-post guard · Rear splash guard · Quick changing tool post · Grinding attachment |

Specification | Unit | AL-1600H |

Max. swing over bed | mm | 1600 |

Max. swing over cross slide | mm | 1250 |

Distance between centers | mm | 3000~20000 |

Max. torque of chuck | N.m | 80000 |

Bed width | mm | 1600 (3 slideway) |

Loading capacity | tons | 32 |

Spindle taper | - | 75° |

Chuck diameter | mm | 1600 |

Spindle speed range | rpm | 0.8-160 (stepless) |

Range of longitudinal feed | mm | 0.125-48 (18) |

Range of cross feed | mm | 0.063-24 (18) |

Metric thread | mm | 2-40 |

Inch thread | TPI | 1-14 |

Module thread | MP | 1.5-20 |

Max. travel of cross slide | mm | 725 |

Max. travel of top slide | mm | 600 |

Section of tool shank | mm | 70x70 |

Tailstock quill daimeter | mm | 300 |

Tailstock quill travel | mm | 300 |

Tailstock quill taper | - | 100, 1:7 |

Tailstock rapid feed speed | mm/min | 3000 |

Tailstock quill rapid feed speed | mm/min | 664 |

Main motor power | kw | 75 |

Machine length | mm | 13577~21577 |

Machine width | mm | 2479 |

Machine height | mm | 2280 |

Machine Details

Spindle box:

For the giant lathes, the spindle through hole diameter 85mm, box split structure, high contact rigidity; The spindle using front

and back support type two-point support mechanical structure, so that the big lathes's radial run-out and axial run-out, high

rotation accuracy. High-frequency quenching and precision grinding of gear, high precision, smooth operation, low noise.

and back support type two-point support mechanical structure, so that the big lathes's radial run-out and axial run-out, high

rotation accuracy. High-frequency quenching and precision grinding of gear, high precision, smooth operation, low noise.

Why Choose Us

Renishaw laser interferometer:

Before the delivery, it adopts UK RENISHAW laser to do dynamic precision testing and offset, so the machine has the high positioning accuracy and re-positioning accuracy.

Company Introduction

Want to Know more details about this product