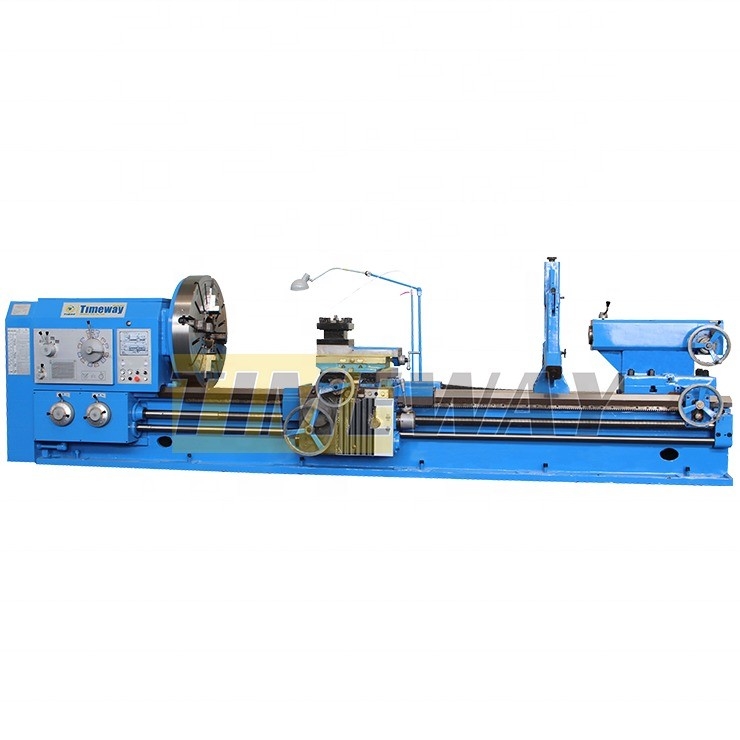

18000 KG Weight Heavy Duty Popular Horizontal Lathe Machine Tools with and ISO32 Oil

Product Details:

| Place of Origin: | China |

| Brand Name: | Timeway |

| Model Number: | AL-1400B/6000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $80,000.00/sets 1-2 sets |

| Packaging Details: | Woode case/Pallet |

| Supply Ability: | 150 Set/Sets per Month |

|

Detail Information |

|||

| Max. Length Of Workpiece (mm): | 6000 | Range Of Spindle Speed(r.p.m): | 3.15 - 315 R.p.m |

|---|---|---|---|

| Machining Capacity: | Heavy Duty | Width Of Bed (mm): | 755 |

| Type: | Horizontal | Spindle Motor Power(kW): | 22 |

| Voltage: | 380V, 50/60HZ | Dimension(L*W*H): | 9100x2150x1950mm |

| Weight (KG): | 18000 KG | Warranty: | 1 Year |

| Key Selling Points: | High Rigidity | Marketing Type: | Ordinary Product |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | After-sales Service Provided: | Engineers Available To Service Machinery Overseas |

| Machine Style: | Heavy Duty Horizontal Lathe Machine | Bed Width: | 755mm |

| Max. Workpiece Weight: | 6000kg (8000kg) | CW Spindle Speed: | 3.15-315 Rpm (21steps) |

| CCW Spindle Speed: | 3.5-291 Rpm (12steps) | Tool Post Swivel Angle: | 90degree |

| Tool Section Size: | 45x45mm | Machine Oil No.: | ISO32# Oil |

| Machine Color: | Customer Optional | Condition: | New |

| Spindle Bore(mm): | 130 | Applicable Industries: | Garment Shops, Building Material Shops, Machinery Repair Shops, Food & Beverage Factory, Printing Shops, Construction Works , Energy & Mining, Advertising Company |

| Showroom Location: | Egypt, Canada, United Kingdom, United States, Italy, France, Germany, Brazil, Peru, Mexico, Russia, Spain, Morocco, Chile, Colombia, Algeria, Romania, Ukraine, Uzbekistan, Australia | Core Components: | Bearing, Pump, Gear, Motor, Gearbox |

| Max. Turned Length (mm): | 5850 Mm | Year: | 2021 |

| Port: | China Port | ||

Product Description

Products Description

Features:

Lathes are suitable for turning inner and outer cylindrical surfaces, conical surfaces and other rotating parts.

They can process all kinds of commonly used metric, inch, modulus and radial threads, and can cut oil grooves and keyways.

Mature structure: The machine tool is solid work, strong in rigidity, high in power, wide in speed range, and capable of high-speed and powerful cutting. Stable performance: It is suitable for stable and strong cutting of large and medium-sized parts such as castings, rigid parts and non-ferrous metals. Highly rigid bed: The bed is made of cast structural bed. The internal ribs have a reasonable layout and high rigidity, and the guide rail adopts an intermediate frequency quenching grinding process. In the sliding guide surface, the anti-crawling guide plate technology is adopted, and the dynamic characteristics such as the friction damping coefficient are in an optimal state, thereby avoiding the occurrence of low-speed crawling.

High rigidity and high precision spindle: The machine tool spindle bearing adopts famous brand products.

The spindle box adopts a symmetrical structure to make the thermal deformation uniform and avoid the offset of the center of the spindle.

To reduce thermal deformation, the headstock is lubricated with an oil bath cycle. The front end of the main shaft adopts a three-support structure of a two-way angular contact ball bearing.

Improve accuracy and increase rigidity.

The gears in the headstock are quenched and grounded to ensure accurate transmission and low noise. The well-assembled spindle has the characteristics of low temperature rise, small

thermal deformation and high precision, which makes the spindle maintain relatively stable accuracy during long-term operation.

High torsion-resistant flat bed, high-quality cast iron carefully manufactured, and induction on the rail surface quenching precision treatment, by the sticky PTFE conductive rails and precision scraping by hand.

thermal deformation and high precision, which makes the spindle maintain relatively stable accuracy during long-term operation.

High torsion-resistant flat bed, high-quality cast iron carefully manufactured, and induction on the rail surface quenching precision treatment, by the sticky PTFE conductive rails and precision scraping by hand.

Spindle standard through the hole for the Ф100mm large hole;

Large speed range with 18 speeds for machining a wide variety of workpieces.

Adopt split type bed structure,the guide rail surface adopt double V-flat rails, 550mm bed width and the bearing capacity can be to 2000kg.

Specification | Unit | AL-1000B | AL-1250B | AL-1400B | AL-1600B | |||

Max. swing over bed | mm | 1000 | 1250 | 1400 | 1640 | |||

Max. swing over cross slide | mm | 615 | 865 | 1015 | 1250 | |||

Distance between centers | mm | 1500/2000/3000/4000/5000/6000/8000/10000/12000/- | ||||||

Max. turning length | mm | 1300/1800/2800/3800/4800/5800/7800/9800/11800/- | ||||||

Bed width | mm | 755 | 755 | 755 | 755 | |||

Loading capacity | kg | 6000 (opt: 8000) | 6000 (opt: 8000) | 6000 (opt: 8000) | 6000 (opt: 8000) | |||

Spindle nose | - | A2-15 (8xM22) | A2-15 (8xM22) | A2-15 (8xM22) | A2-15 (8xM22) | |||

Spindle bore | mm | 130 | 130 | 130 | 130 | |||

Spindle taper | - | Metric 140 | Metric 140 | Metric 140 | Metric 140 | |||

Spindle speed range | rpm | Forward: 3.15-315, CW: 3.5-291 | ||||||

Spindle speed step | steps | Forward: 21, Reverse: 12 | ||||||

X/Z-axis feed kinds | kinds | 56/56 | 56/56 | 56/56 | 56/56 | |||

Feed range | mm | Longitudinal: 0.1-12; Cross: 0.05-6; Top tool-post: 0.025-3 | ||||||

Metric threads range (kinds) | mm | 1-120 (44) | 1-120 (44) | 1-120 (44) | 1-120 (44) | |||

Inch threads range (kinds) | TPI | 28-1/4 (31) | 28-1/4 (31) | 28-1/4 (31) | 28-1/4 (31) | |||

Module threads range (kinds) | MP | 0.5-60 (45) | 0.5-60 (45) | 0.5-60 (45) | 0.5-60 (45) | |||

Diametrical threads range (kinds) | DP | 1/2-56 (38) | 1/2-56 (38) | 1/2-56 (38) | 1/2-56 (38) | |||

Distance spindle center to tool base | mm | 48 | 48 | 48 | 48 | |||

Tool post swivel angle | ° | ±90° | ±90° | ±90° | ±90° | |||

Cross slide travel | mm | 520 | 580 | 580 | 630 | |||

Top slide travel | mm | 300 | 300 | 300 | 300 | |||

Tool section size | mm | 45x45 | 45x45 | 45x45 | 45x45 | |||

Rapid feed speed | mm/min | Longitudinal: 3740; Cross: 1870; Top tool-post: 935 | ||||||

Tailstock quill diameter | mm | 160 | 160 | 160 | 160 | |||

Tailstock quill travel | mm | 300 | 300 | 300 | 300 | |||

Tailstock quill taper | - | MT6 | MT6 | MT6 | MT6 | |||

Main motor power | kw | 22 | 22 | 22 | 22 | |||

Machine length | mm | 4600/5100/6100/7100/8100/9100/11100/13100/15100/- | ||||||

Machine width | mm | 2150 | 2150 | 2150 | 2150 | |||

Machine height | mm | 1700 | 1825 | 1950 | 2150 | |||

Why Choose Us

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product