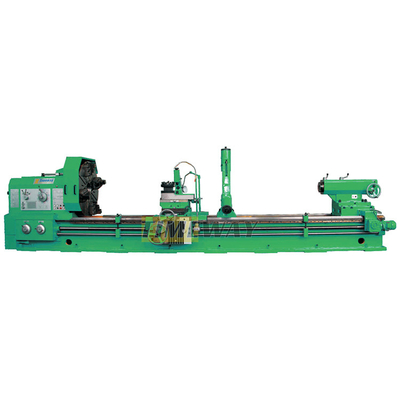

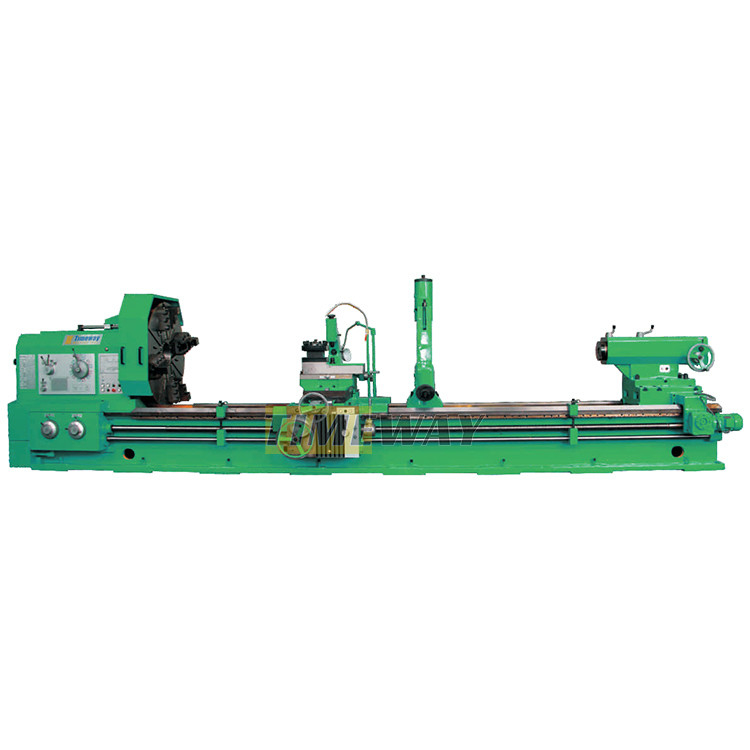

1100mm Bed Width Conventional Metal Manual Lathe for High Productivity Steel Machining

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | TIMAC |

| Model Number: | AL-1250 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $15,000.00/sets 1-1 sets |

| Packaging Details: | in wooden case (can be fumigated) or plywood case |

| Supply Ability: | 100 Set/Sets per Month |

|

Detail Information |

|||

| Max. Length Of Workpiece (mm): | 12000 | Range Of Spindle Speed(r.p.m): | 3.15 - 315 R.p.m |

|---|---|---|---|

| Machining Capacity: | Heavy Duty | Width Of Bed (mm): | 1100 |

| Type: | Horizontal | Spindle Motor Power(kW): | 30 |

| Voltage: | 220V, 380V, 400V, 415V, 440V | Dimension(L*W*H): | 7120x2430x2580 Mm |

| Weight (KG): | 17000 KG | Warranty: | 1 Year |

| Key Selling Points: | High Productivity | Marketing Type: | Ordinary Product |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | Max. Swing Diameter Over Bed: | 2000 Mm |

| Max. Swing Diameter Over Cross Slide: | 1650 Mm | Cross Travel: | 900 Mm |

| Carriage Longitudinal Travel: | 4000 Mm | Top Tool-post Travel: | 360 Mm |

| Max. Weight Of The Workpiece: | 16tons (20tons) | Spindle Nose: | A2-15 |

| Spindle Taper: | Metric 140 | Tailstock Quill Taper: | Metric 80 |

| Tailstock Quill Diameter: | 300 Mm | Condition: | New |

| Spindle Bore(mm): | 100 | Applicable Industries: | Manufacturing Plant |

| Showroom Location: | Canada, United States, Italy, Germany, Mexico, Russia, Spain, South Africa, Australia | Core Components: | Bearing, Pump, Gear, Motor, Gearbox, Pressure Vessel |

| Max. Turned Length (mm): | 11800 Mm | Year: | New |

| Port: | China Port | ||

Product Description

Products Description

Heavy Duty Horizontal Lathe AL-1250

Technical Parameter

Specifications | Unit | AL-1250 | AL-1400 | AL-1600 | ||

Swing over bed | mm | 1250 | 1440 | 1600 | ||

Swing over carriage | mm | 900 | 1050 | 1250 | ||

Max. length of workpiece | mm | 3000/4000/5000/6000/8000/10000/12000 | 1000-16000 | 3000/4000/5000/6000/8000/10000/12000 | ||

Max. turning length | mm | 2800/3800/4800/5800/7800/9800/11800 | 800-15800 | 2800/3800/4800/5800/7800/9800/11800 | ||

Span of guideway | mm | 1100 | 1100 | 1100 | ||

Max. weight of workpiece | t | 16 | 16 | 16 | ||

Spindle nose | - | A2-15 | A2-15 | A2-15 | ||

Spindle bore | mm | 100 | 130 | 100 | ||

Taper hole of spindle | - | metric 140 | Metric 140 | metric 140 | ||

Range of spindle speeds | r/min | foreward: 3.15-315, reversal: 3.5-291 | foreward: 3.15-315, reversal: 3.5-290 | foreward: 3.15-315, reversal: 3.5-291 | ||

No. of spindle speeds | steps | foreward: 21, reversal: 12 | foreward: 21, reversal: 12 | foreward: 21, reversal: 12 | ||

Longitudinal and cross | kinds | 56 | 56 | 56 | ||

Feed per revolution | mm/r | long longitudinal:0.1-12, cross:0.05-6, top tool-post:0.025-3 | long longitudinal:0.1-12, cross:0.05-6 | long longitudinal:0.1-12, cross:0.05-6, top tool-post:0.025-3 | ||

No. and range of metric thread | mm | 1-120 (44) | 1-120 (44) | 1-120 (44) | ||

No. and range of inch thread | TPI | 28-1/4 (31) | 3/8-28 (31) | 28-1/4 (31) | ||

No. and range of module thread | MP | 0.5-60 (45) | 0.5-60 (45) | 0.5-60 (45) | ||

No. and range of dia. thread | DP | 1/2-56 (38) | 1-56 (25) | 1/2-56 (38) | ||

Distance of spindle and tool plane | mm | 53 | 53 | 53 | ||

Tool post swing range | ° | ±90 | ±90 | ±90 | ||

Max. travel of cross slide | mm | 740 | 800 | 850 | ||

Max. travel of top slide | mm | 360 | 360 | 360 | ||

Section of tool shank | mm | 50x50 | 50x50 | 50x50 | ||

Travel of tool post (per turn of dials) | mm | 0.05 | 0.05 | 0.05 | ||

Dia. of tailstock quill | mm | 260 | 260 | 260 | ||

Travel of tailstock quill | mm | 300 | 300 | 300 | ||

Taper hole of tailstock quill | - | Metric 80 | Metric 80 | Metric 80 | ||

Main motor power | kw | 30 | 30 | 30 | ||

Standard accessories: Optional accessories:

· 4-jaw independent chuck · Steady rest (over 3M length) · Follow rest (over 3M length) · Electric moving tailstock · Dead center of tailstock · 4-station tool post · Cooling system · Work lamp · Tools & tool-box · Leveling wedge and bolts Operation manual (English) | · Face plate · 2 or 3-axis digital indicator · Chuck guard · Tool-post guard · Rear splash guard Quick changing tool post |

Detail Images

Our Team

Why Choose Us

FAQ

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

A: 1 . High quality with competitive price;

2 . Professional R&D team and 25 years export experience;

3 . Exported more than 60 countries;

4 . CE, ISO Certificates;

5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager);

6 . 12 months quality warranty;

7 . Oversea engineers available for problem resolving;

Q: Do you have QC or any safety standards for your machinery?

A: yes, we have established a highly strict quality control department to guanrantee good quality.

Q: What's the MOQ?

A: 1 set (Only some low cost machines will be more than 1 set )

Q: What about the payment terms?

A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment;

(2) Irrevocable LC at sight;

(3) Western Union, MoneyGram, etc.

Q: How about the warranty?

A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product