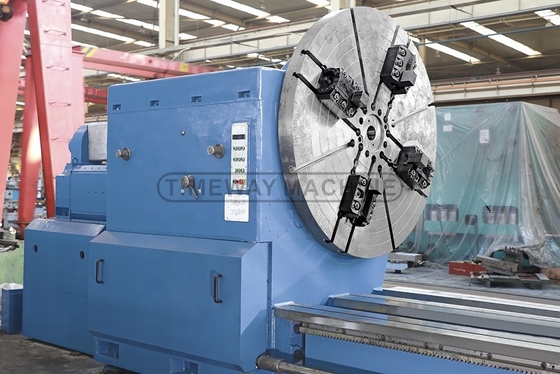

Timeway AL-2500H High Precision Heavy Duty Horizontal Lathe 75kW Spindle Motor Power

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | Timac |

| Model Number: | AL-2500H |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $450,000.00/sets 1-2 sets |

|

Detail Information |

|||

| Max. Length Of Workpiece (mm): | 10000 | Range Of Spindle Speed(r.p.m): | 0.8 - 160 R.p.m |

|---|---|---|---|

| Machining Capacity: | Medium Duty | Type: | Horizontal |

| Spindle Motor Power(kW): | 75 | Voltage: | 220V/440V |

| Dimension(L*W*H): | 13577x2515x2655 Mm | Weight (KG): | 40000 KG |

| Warranty: | 1 Year | Key Selling Points: | Easy To Operate |

| Marketing Type: | Ordinary Product | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 1 Year |

| Max. Swing Over Bed: | 2500mm | Max. Swing Over Cross Slide: | 2200mm |

| Distance Between Centers: | 10000mm | Max. Torque Of Chuck: | 80000N.m |

| Bed Width: | 1600mm | Loading Capacity: | 32tons |

| Spindle Taper: | 75° | Range Of Longitudinal Feed: | 0.125-48 (18)mm |

| Range Of Cross Feed: | 0.063-24 (18)mm | Metric Thread: | 2-40mm |

| Condition: | New | Applicable Industries: | Home Use, Retail, Construction Works |

| Showroom Location: | France, Peru, Saudi Arabia, Spain, South Korea | Core Components: | Bearing |

| Spindle Bore(mm): | 100 Mm | Max. Turned Length (mm): | 9800 Mm |

| Year: | 2019 | ||

Product Description

Summary

This machine is a universal lathe with loading capacity of 25/32/40 tons, after used roller support and steady rest, loading capacity to be 40tons. It is suitable for high-speed steel and hard alloy steel tools. For shaft parts of different materials, cylindrical and disc-shaped parts, turning outer ring, end face, slotting, cutting, The boring, the inner and outer cones of the rut, and the use of the upper tool holder (via the hanging wheel) for turning various threads of less than 600 mm in length.

Features:

1. The machine bed is integral box-shaped three rectangular rail structure, which is cast in one-time casting with high-grade cast iron (HT 300). After two times of aging treatment, the stability is good; the width of the guide rail is 1600 mm, the rigidity is good, and the anti-vibration capability is strong; Precision grinding by imported guide grinding machines ensures long life, high precision and good retention.

2. The main drive mechanism of the machine tool is driven by a 75 KW DC motor. The total speed ratio of the variable speed control mode is 1:22.2,3 steps speed changing, and the mechanical and electrical speed ratio is 1:200. The spindle obtains a stepless speed regulation range of 0.8 to 160 r/min.

1. The machine bed is integral box-shaped three rectangular rail structure, which is cast in one-time casting with high-grade cast iron (HT 300). After two times of aging treatment, the stability is good; the width of the guide rail is 1600 mm, the rigidity is good, and the anti-vibration capability is strong; Precision grinding by imported guide grinding machines ensures long life, high precision and good retention.

2. The main drive mechanism of the machine tool is driven by a 75 KW DC motor. The total speed ratio of the variable speed control mode is 1:22.2,3 steps speed changing, and the mechanical and electrical speed ratio is 1:200. The spindle obtains a stepless speed regulation range of 0.8 to 160 r/min.

Product Description

Horizontal Heavy Duty Big Lathes AL-2500H

Specification

Specification | Unit | AL-2500H |

Max. swing over bed | mm | 2500 |

Max. swing over cross slide | mm | 2200 |

Distance between centers | mm | 10000 |

Max. torque of chuck | N.m | 80000 |

Bed width | mm | 1600 |

Loading capacity | tons | 32 |

Spindle taper | - | 75° |

Range of longitudinal feed | mm | 0.125-48 (18) |

Range of cross feed | mm | 0.063-24 (18) |

Metric thread | mm | 2-40 |

Accessories

Standard accessories:

• 4-jaw independent chuck

• Steady rest

• Dead center of tailstock

• Cooling system

• Work lamp

• Electric moving tailstock

• Tools & tool-box

• Leveling wedge and bolts

• Operation manual (English)

• Steady rest

• Dead center of tailstock

• Cooling system

• Work lamp

• Electric moving tailstock

• Tools & tool-box

• Leveling wedge and bolts

• Operation manual (English)

Optional accessories:

• Face plate

• 2 or 3-axis digital indicator

• Chuck guard

• Tool-post guard

• Rear splash guard

• Roller support

• 2 or 3-axis digital indicator

• Chuck guard

• Tool-post guard

• Rear splash guard

• Roller support

Three slideway rails:

The big heavy duty adopts the three slideway rails structure, bed width is up to 1600 mm, high rigidity and strong anti-vibration so that the loading capacity 40 tons. The lathes' rails adopt medium-frequency hardened (HRC68), and ground by imported rail grinding machine. So the heavy duty have long-service life, high rigidity, and good stable.

Tialstock:

High rigidity and large loading capacity.

Tailstock diameter: 400mm

Center tapered angle: 75°

Tailstock effective travel: 300mm

Tailstock cross moving stroke: 15mm

Tailstock diameter: 400mm

Center tapered angle: 75°

Tailstock effective travel: 300mm

Tailstock cross moving stroke: 15mm

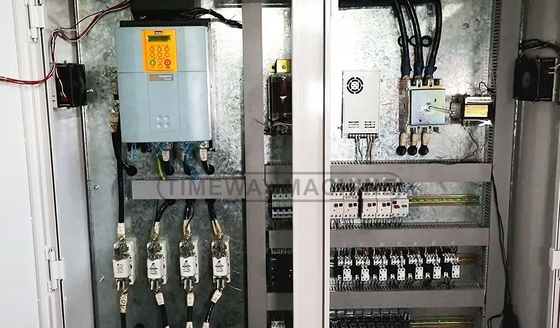

Electric cabinet:

Clearly wire layout, CE marks electrical components.

DC 75kw main motor:

The heavy duty lathes can gain spindle speed 0.8-160rpm with stepless, the main transmission structure is driven by the DC 75KW main motor, large torque and strong turning force for the heavy duty cutting, the spindle speed is adjusted through adjustment of the pressure and magnetism.

Spindle box:

For the giant lathes, the spindle through hole diameter 85 mm, box split structure, high contact rigidity; The spindle using front and back support type two-point support mechanical structure, so that the big lathes's radial run-out and axial run-out, high rotation accuracy. High-frequency quenching and precision grinding of gear, high precision, smooth operation, low noise.

Carriage:

The lathes feed system is connected to the main drive through the light bar, so that the feed is directly related to the spindle speed, and the feed rate is covenient to select. Two rows of high precision racks are installed on front and behind the giant heavy duty lathes, the front racks drives the carriage feed to realize turning threads, and the behind rack drives foe motorized movement.

Packing & Delivery

This is the picture of the packaging in our factory! You can see our package is standardized and centralized , then they will be shipped to your designated place.

Company Profile

Timeway Machine Tool Co., Ltd. is a professional machine tool manufacturing enterprises, the main products include lathe, milling machine, grinding machine, etc., and according to customer needs we also can design and manufacture various special purpose machines, to provide relative technology upgrading and transformation services in machine tool field.

Our factory was established in 2014. It has professional technicians, a research and development team, manufactures and sells CNC equipment and provides professional customized services.Our products are widely used in mold processing, 3C products, agricultural machinery, petroleum machinery, auto parts processing, aerospace industry, etc., selling more than 60 countries and regions in domestic and abroad.

Certifications

Since our company established, we have obtained many certificates. The above picture is for your reference. We will continue to provide excellent machine tools for domestic and foreign users.

FAQ

Q: Why choose TIMEWAY MACHINE?

A:1 . High quality with competitive price; 2 . Professional R&D team and 25 years export experience; 3 . Exported more than 60 countries; 4 . CE, ISO Certificates; 5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager); 6 . 12 months quality warranty; 7 . Oversea engineers available for problem resolving; Q: Do you have QC or any safety standards for your machinery? A: yes, we have established a highly strict quality control department to guanrantee good quality. Q: What's the MOQ? A: 1 set (Only some low cost machines will be more than 1 set ) Q: What about the payment terms? A:(1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment; (2) Irrevocable LC at sight; (3) Western Union, MoneyGram, etc. Q: How about the warranty? A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product