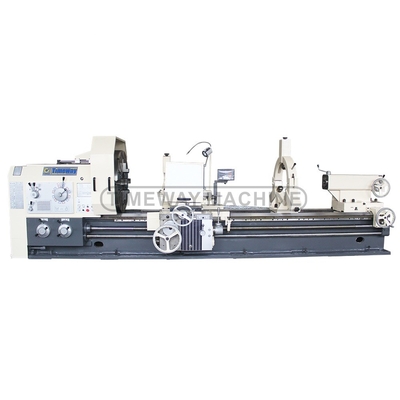

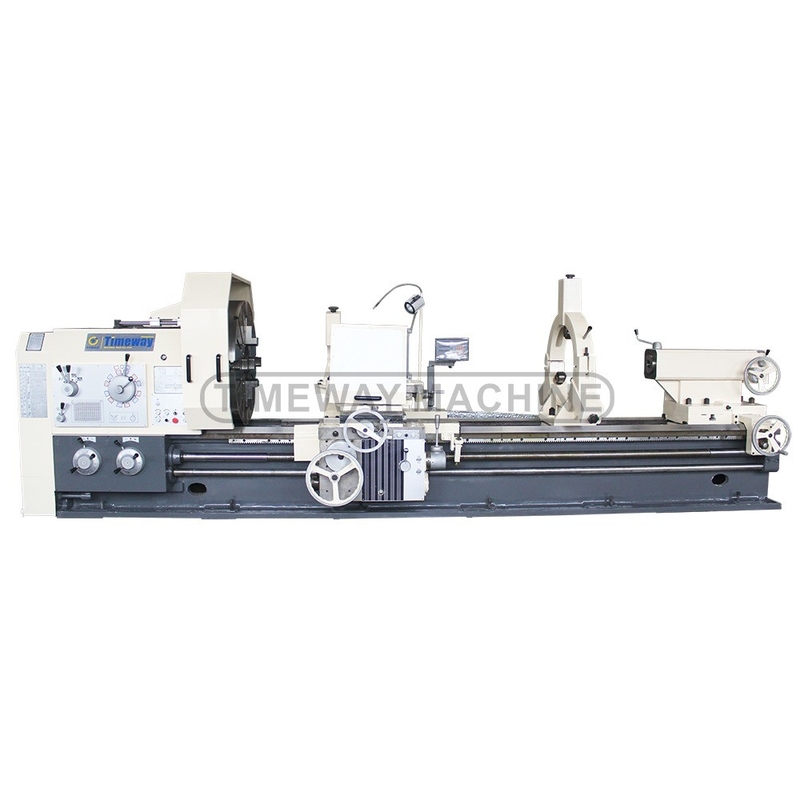

Large Diameter Horizontal Lathe Machine with Competitive Heavy Duty Universal Lathe

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | timeway |

| Model Number: | AL-1000B/2000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $48,000.00/sets 1-2 sets |

| Packaging Details: | Wooden cases(can be fumigated) |

| Supply Ability: | 150 Set/Sets per Month |

|

Detail Information |

|||

| Max. Length Of Workpiece (mm): | 2000 | Range Of Spindle Speed(r.p.m): | 3.15 - 315 R.p.m |

|---|---|---|---|

| Machining Capacity: | Heavy Duty | Type: | Horizontal |

| Spindle Motor Power(kW): | 22 | Voltage: | 380V 50HZ 3PH Or Negotiable |

| Dimension(L*W*H): | 5100*2150*1700mm | Weight (KG): | 20000 KG |

| Warranty: | 1 Year | Key Selling Points: | Competitive Price |

| Marketing Type: | Ordinary Product | Machinery Test Report: | Provided |

| Video Outgoing-inspection: | Provided | Warranty Of Core Components: | 1 Year |

| Name: | Heavy Duty Horizontal Lathe | Machine Type: | Horizontal Metal Turning Lathe Machine |

| CNC Or Not: | Normal Lathe Machine | Max. Swing Over Bed: | 1000mm |

| Distance Between Centers: | 1500/2000/3000/ 4000/5000/6000 | Model: | AL-1000B/2000 |

| Color: | Customized Option | Motor Power: | 22KW |

| After-sales Service Provided: | 12 Months | Spindle Bore: | 130mm |

| Condition: | New | Spindle Bore(mm): | 130 |

| Applicable Industries: | Machinery Repair Shops, Manufacturing Plant, Home Use, Construction Works , Energy & Mining | Showroom Location: | Russia, Spain, Thailand, South Korea, Colombia |

| Core Components: | Bearing, Pump, Gear, Motor, Gearbox | Max. Turned Length (mm): | 1800 Mm |

| Port: | China Port | ||

Product Description

Products Description

High Precision Horizontal lathe machine

Product Paramenters

Specifications | Unit | AL-1000B | AL-1250B | |

Swing over bed | mm | 1000 | 1250 | |

Swing over carriage | mm | 615 | 865 | |

Max. length of workpiece | mm | 1500/2000/3000/4000/5000/6000/8000/10000/12000 | ||

Max. turning length | mm | 1300/1800/2800/3800/4800/5800/7800/9800/11800 | ||

Span of guideway | mm | 755 | 755 | |

Max. weight of workpiece | kg | 6000 | 6000 | |

Spindle nose | - | A2-15 | A2-15 | |

Spindle bore | mm | 130 | 130 | |

Taper hole of spindle | Metric 140 | Metric 140 | ||

Range of spindle speeds | r/min | foreward:3.15-315, reversal:3.5-291 | foreward:3.15-315, reversal:3.5-291 | |

No. of spindle speeds | steps | foreward:21, reversal:12 | foreward:21, reversal:12 | |

No. of longitudinal and cross | kinds | 56/56 | 56/56 | |

Feed per revolution | mm | long longitudinal:0.1-12, Cross:0.05-6, top tool-post:0.025-3 | ||

No. and range of metric thread | mm | 1-120 (44) | 1-120 (44) | |

No. and range of inch thread | TPI | 28-1/4 (31) | 28-1/4 (31) | |

No. and range of module thread | MP | 0.5-60 (45) | 0.5-60 (45) | |

No. and range of dia. thread | DP | 1/2-56 (38) | 1/2-56 (38) | |

Distance of spindle and tool plane | mm | 48 | 48 | |

Tool post swing range | ° | ±90 | ±90 | |

Max. travel of cross slide | mm | 520 | 580 | |

Max. travel of top slide | mm | 300 | 300 | |

Section of tool shank | mm | 45x45 | 45x45 | |

Rapid travel speeds | mm/min | longitudinal: 1870, Cross: 3740, top tool-post: 935 | ||

Dia. of tailstock quill | mm | 160 | 160 | |

Travel of tailstock quill | mm | 300 | 300 | |

Taper hole of tailstock quill | - | MT6 | MT6 | |

Main motor power | kw | 22 | 22 | |

Details of Accessories:

* 3-jaw chuck * Steady rest (over 3M length) * Follow rest (over 3M length) * Manual moving tailstock * Dead center of tailstock * 4-station tool post * Cooling system * Work lamp * Tools & tool-box * Leveling wedge and bolts * Operation manual (English) | * 4-jaw independent chuck * Face plate * 2 or 3-axis digital indicator * Chuck guard * Tool-post guard * Rear splash guard * Quick changing tool post * Grinding attachment |

Positive Comments From Customers

Our Services

1. Free replacing parts available in the warranty period. Cost price replacing parts available beyond the warranty period. 2. Quick action and reply for the technical questions at any time in the whole life of the machine. 3. Overseas after service center available in some region. 4. Engineer overseas service available on the requirement of customer(relative cost born by customer).

Company Introduction

Factory Display:

Factory Profile:

Our factory was established in 2014. It has professional technicians, a research and development team, manufactures and sells CNC equipment and provides professional customized services.Our products are widely used in mold processing, 3C products, agricultural machinery, petroleum machinery, auto parts processing, aerospace industry, etc., selling more than 60 countries and regions in domestic and abroad.

Text Introduction:

Company Profile:

Timeway Machine Tool Co., Ltd. is a professional machine tool manufacturing enterprises, the main products include lathe, milling machine, grinding machine, etc., and according to customer needs we also can design and manufacture various special purpose machines, to provide relative technology upgrading and transformation services in machine tool field.

FAQ

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price; 2 . Professional R&D team and 25 years export experience; 3 . Exported more than 60 countries; 4 . CE, ISO Certificates; 5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager); 6 . 12 months quality warranty; 7 . Oversea engineers available for problem resolving; Q: Do you have QC or any safety standards for your machinery? A: yes, we have established a highly strict quality control department to guanrantee good quality. Q: What's the MOQ? A: 1 set (Only some low cost machines will be more than 1 set ) Q: What about the payment terms? A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment; (2) Irrevocable LC at sight; (3) Western Union, MoneyGram, etc. Q: How about the warranty? A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product