800mm Swing Q-325F Metal Lathes Large Spindle Bore and Rapid Feed Speed 0 3740 mm/min

Product Details:

| Place of Origin: | Henan, China |

| Brand Name: | TIMEWAY |

| Model Number: | Q-325F |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 set |

|---|---|

| Price: | $36,660.00/sets 1-2 sets |

|

Detail Information |

|||

| Max. Length Of Workpiece (mm): | 3000 | Range Of Spindle Speed(r.p.m): | 20 - 100 R.p.m |

|---|---|---|---|

| Machining Capacity: | Heavy Duty | Type: | Horizontal |

| Weight (KG): | 9000 KG | Warranty: | 1 Year |

| Key Selling Points: | Competitive Price, High Safety Level, High-accuracy, Energy Saving, Sustainable, High Productivity, Long Service Life, Easy To Operate, Flexible Manufacturing, High Rigidity | Marketing Type: | New Product 2024 |

| Machinery Test Report: | Provided | Video Outgoing-inspection: | Provided |

| Warranty Of Core Components: | 1 Year | Max. Weight Of Workpiece(kg): | 3000 |

| Spindle Taper: | Other | Cutting Torque: | 150 N.m |

| Rapid Feed Speed(mm/min): | 0 - 3740 Mm/min | Feed Speed(mm/min): | 0 - 1870 Mm/min |

| Tool Post Stations: | 4 | Name: | Oil Country Lathe |

| Machine Type: | Horizontal Normal Lathe | Keyword: | Turning Machine |

| Function: | Machining Metal | Precision: | High Precision |

| Processing: | Metal Workpiece | Distance Between Centers: | 1000/1500/2000/3000mm |

| Swing Over Bed: | 800mm | Color: | Customrized |

| Pipe Threading Range: | 70-320mm | ||

Product Description

One-Stop Shopping

You can click on the picture to view the products you are interested in

Products Description

Features:

1.This machine was designed for use in often harsh and demanding environment associated with OCTG production and integrates decadesof experience.

2.Lathe adopts standard cast iron (HT300) a molding casting, after the second aging treatment, it has feature of stable performance;guide-way width (550/600/650mm), good rigidity, anti-vibration ability; Processed by ultrasonic frequency hardening and machined by theimported guideway rail grinding machine, to ensure a long service life.

3.The spindle box adopts a symmetrical structure to make the thermal deformation uniform and avoid the offset of the center of the spindle. To reduce thermal deformation, the headstock is lubricated with an oil bath cycle.

4.Hardened and precision ground spindle adopts two support structure with high-precision grade bearings, to ensure spindle running stable.

5.Pipe threading lathe with large spindle bore and double hollow chuck on both ends of spindle for long pipes.

7.Equipped with rapid feed motor for X/Z-axis quickly positioning, reduce operating intensity and machining assistance time, improve machining efficiency.

8.Spindle driven by variable frequency motor with interver, realize manual 2steps speed change, within steps variable speed (stepless).

9.Wide spindle speed range for choosing reasonable speed, various steps feed speed for meeting different processing process and threads cutting.

10.The lathe machine is mainly developed for the turning of oil field pipe thread, it is not only suitable for all kinds of pipe

thread turning, but also can be used as ordinary lathe, suitable for processing complex shape of the shaft, disk parts, such as turning inner and outer cylindrical surface, conical surface, end face. Especially for multi-species, small batch of turning processing.

1.This machine was designed for use in often harsh and demanding environment associated with OCTG production and integrates decadesof experience.

2.Lathe adopts standard cast iron (HT300) a molding casting, after the second aging treatment, it has feature of stable performance;guide-way width (550/600/650mm), good rigidity, anti-vibration ability; Processed by ultrasonic frequency hardening and machined by theimported guideway rail grinding machine, to ensure a long service life.

3.The spindle box adopts a symmetrical structure to make the thermal deformation uniform and avoid the offset of the center of the spindle. To reduce thermal deformation, the headstock is lubricated with an oil bath cycle.

4.Hardened and precision ground spindle adopts two support structure with high-precision grade bearings, to ensure spindle running stable.

5.Pipe threading lathe with large spindle bore and double hollow chuck on both ends of spindle for long pipes.

6.Equipped with taper turning attachment, can automatic feed turning inner an outer cone surface and threads.

7.Equipped with rapid feed motor for X/Z-axis quickly positioning, reduce operating intensity and machining assistance time, improve machining efficiency.

8.Spindle driven by variable frequency motor with interver, realize manual 2steps speed change, within steps variable speed (stepless).

9.Wide spindle speed range for choosing reasonable speed, various steps feed speed for meeting different processing process and threads cutting.

10.The lathe machine is mainly developed for the turning of oil field pipe thread, it is not only suitable for all kinds of pipe

thread turning, but also can be used as ordinary lathe, suitable for processing complex shape of the shaft, disk parts, such as turning inner and outer cylindrical surface, conical surface, end face. Especially for multi-species, small batch of turning processing.

Specification | Unit | Q-325F | ||

Swing over bed | mm | Φ800 | ||

Swing over cross slide | mm | Φ480 | ||

Distance between centers | mm | 1000/1500/2000/3000 | ||

Pipe threading range | mm | Φ70-320 | ||

Width of bed way | mm | 600 (Opt. 650) | ||

Spindle bore | mm | Φ325 | ||

Spindle speed steps | - | VF.2steps | ||

Spindle speed range | rpm | 20-100,100-300 | ||

Chuck size | mm | Φ780 | ||

Chuck type | - | 4-jaw manual | ||

Turret type | - | Manual 4 position | ||

Tool shank | mm | 40x40 | ||

X axis travel | mm | 520 | ||

Z axis travel | mm | 800/1300/1800/2800 | ||

X axis rapid traverse speed | mm/min | 1870 | ||

Z axis rapid traverse speed | mm/min | 3740 | ||

X axis feed grade/range | mm/r | 32/0.095-14 | ||

Z axis feed grade/range | mm/r | 32/0.095-14 | ||

Tailstock quill diameter | mm | Φ140 | ||

Tailstock quill taper | - | MT6 | ||

Tailstock quill travel | mm | 250 | ||

Main spindle motor power | kw | 15 | ||

Rapid traverse motor power | kw | 1.5 | ||

Coolant pump motor power | kw | 0.125 | ||

Metric thread grade/range | mm | 22 / 1-15 | ||

Inch thread grade/range | T.P.I | 26 / 14-1 | ||

Machine length | mm | 3700/4200/4700/5700 | ||

Machine width/machine height | mm | 1700x1600 | ||

Machine weight | kg | 8000/8500/9000/10000 | ||

· Big bore chuck (Front & Rear) · Dead center · 4-station tool post · Taper turning attachment · Cooling system · Work lamp · Chip collecting plate · General tools · Leveling wedge and bolts · Operation manual (English) | · 2 or 3-axis DRO · Chuck guard · Too-post guard · Rear splash guard · Rear support for long pipe |

Client feedback

Our Services

1. Free replacing parts available in the warranty period. Cost price replacing parts available beyond the warranty period. 2. Quick action and reply for the technical questions at any time in the whole life of the machine. 3. Overseas after service center available in some region. 4. Engineer overseas service available on the requirement of customer(relative cost born by customer).

Company Introduction

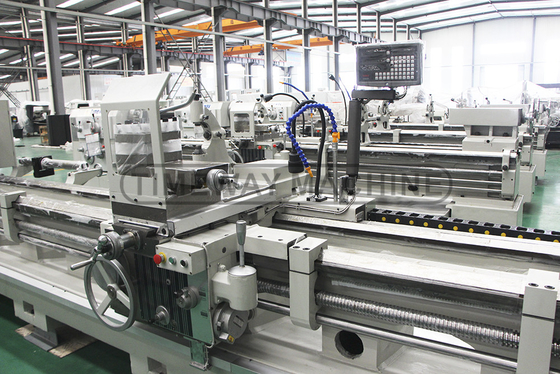

Factory Display:

Factory Profile:

Our factory was established in 2014. It has professional technicians, a research and development team, manufactures and sells CNC equipment and provides professional customized services.Our products are widely used in mold processing, 3C products, agricultural machinery, petroleum machinery, auto parts processing, aerospace industry, etc., selling more than 60 countries and regions in domestic and abroad.

Text Introduction:

Company Profile:

Timeway Machine Tool Co., Ltd. is a professional machine tool manufacturing enterprises, the main products include lathe, milling machine, grinding machine, etc., and according to customer needs we also can design and manufacture various special purpose machines, to provide relative technology upgrading and transformation services in machine tool field.

Customer Visited:

So far, we have received many customers from abroad, and they are all very satisfied with our company and products

Exhibitions:

Since the establishment of the Ministry of Foreign Trade, we have participated in various domestic and international exhibitions such as the Autumn Canton Fair, Beijing Exhibition, Shanghai Exhibition, Moscow, Ethiopia, and Russia, and have maintained long-term friendly cooperative relations with exhibition customers.

FAQ

Q: Why choose TIMEWAY MACHINE?

A: 1 . High quality with competitive price; 2 . Professional R&D team and 25 years export experience; 3 . Exported more than 60 countries; 4 . CE, ISO Certificates; 5 . 24 HOURS ONLINE SERVICE (SKYPE, WhatsApp, Wechat, Trademanager); 6 . 12 months quality warranty; 7 . Oversea engineers available for problem resolving; Q: Do you have QC or any safety standards for your machinery? A: yes, we have established a highly strict quality control department to guanrantee good quality. Q: What's the MOQ? A: 1 set (Only some low cost machines will be more than 1 set ) Q: What about the payment terms? A: (1) T/T with 30% advanced payment, and 70% balance payment to be paid before shipment; (2) Irrevocable LC at sight; (3) Western Union, MoneyGram, etc. Q: How about the warranty? A: Warranty Period is one year after delivery. Even beyond the period, we will supply lifetime service for machine.

Want to Know more details about this product